ADSS Cable

ADSS Fiber Optic Cable: All-Dielectric, High-Tensile Solution for Power & Telecom Networks | OMC Cable

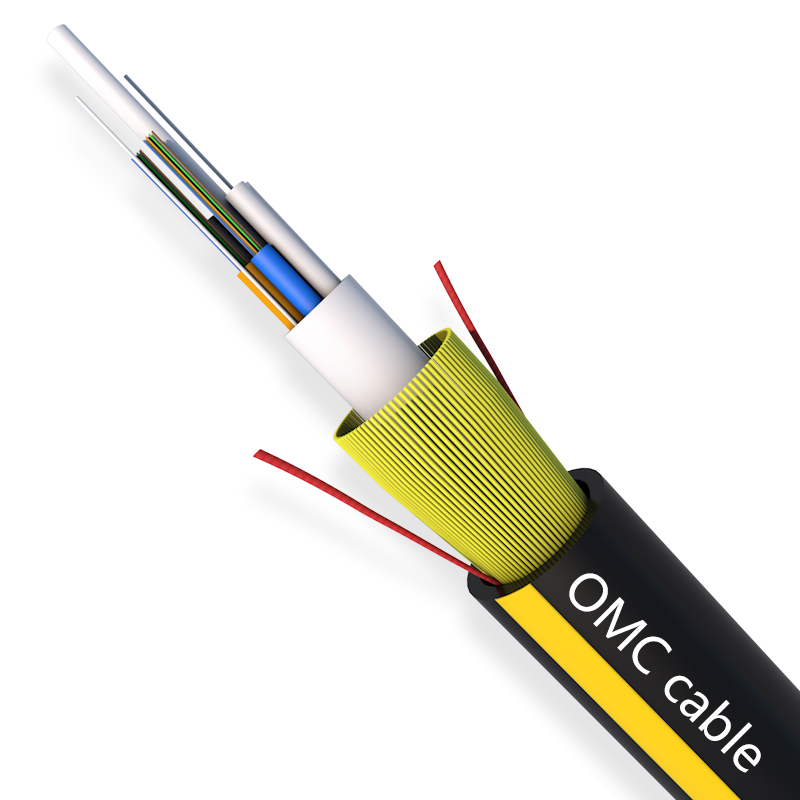

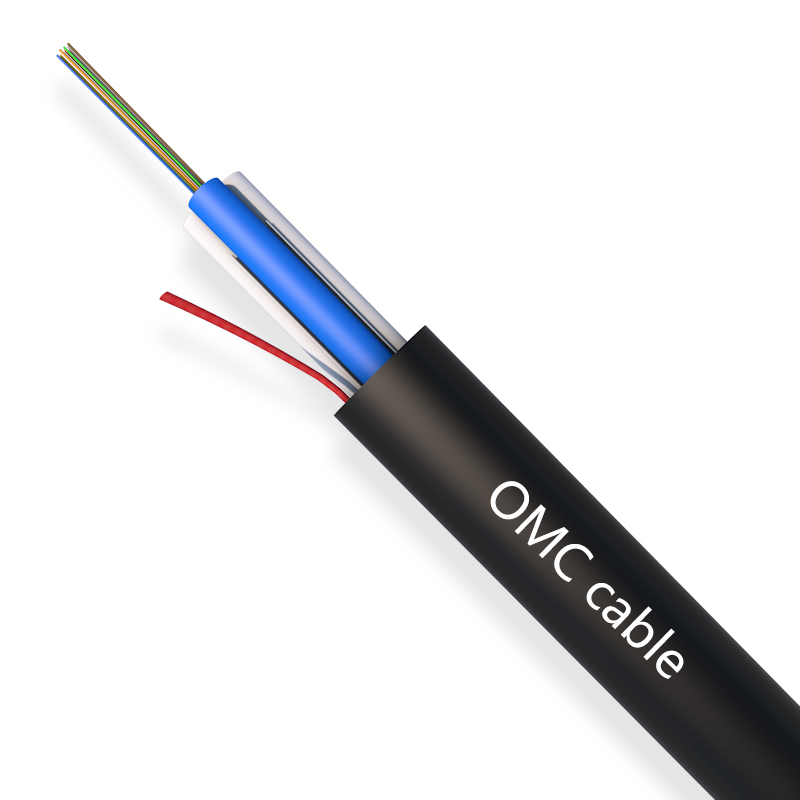

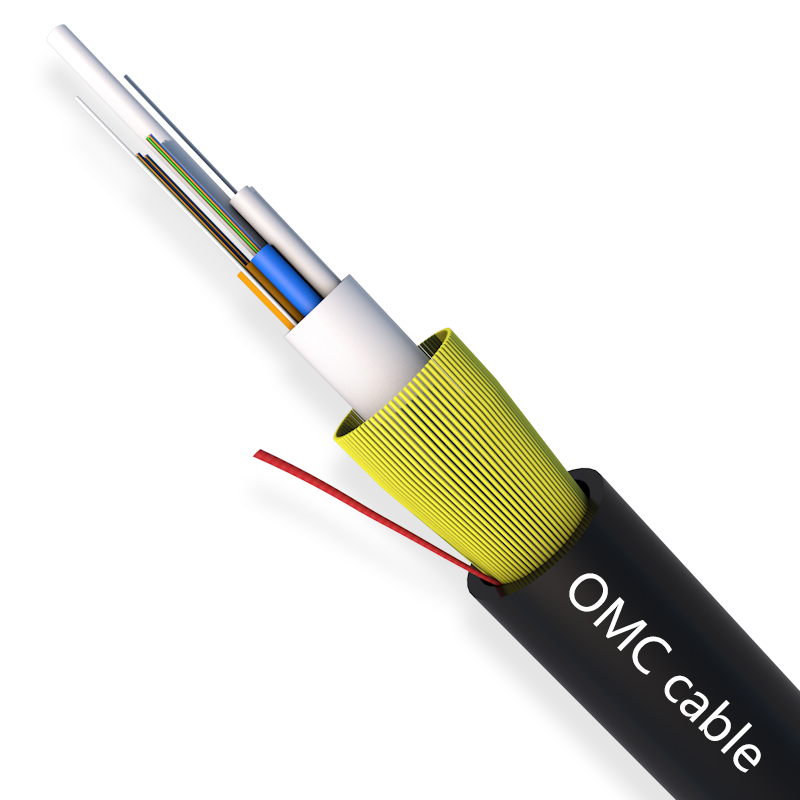

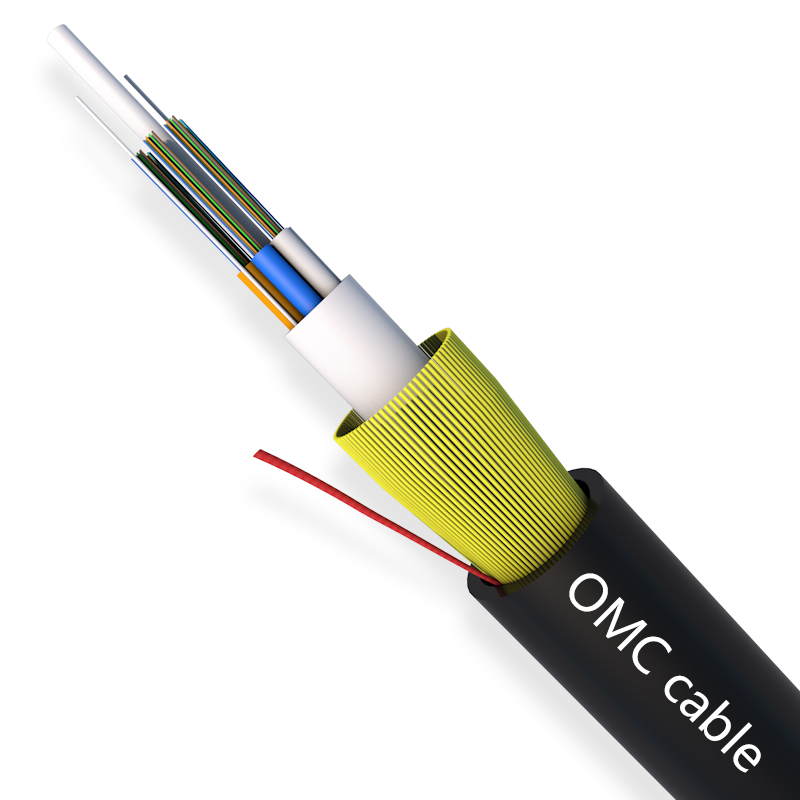

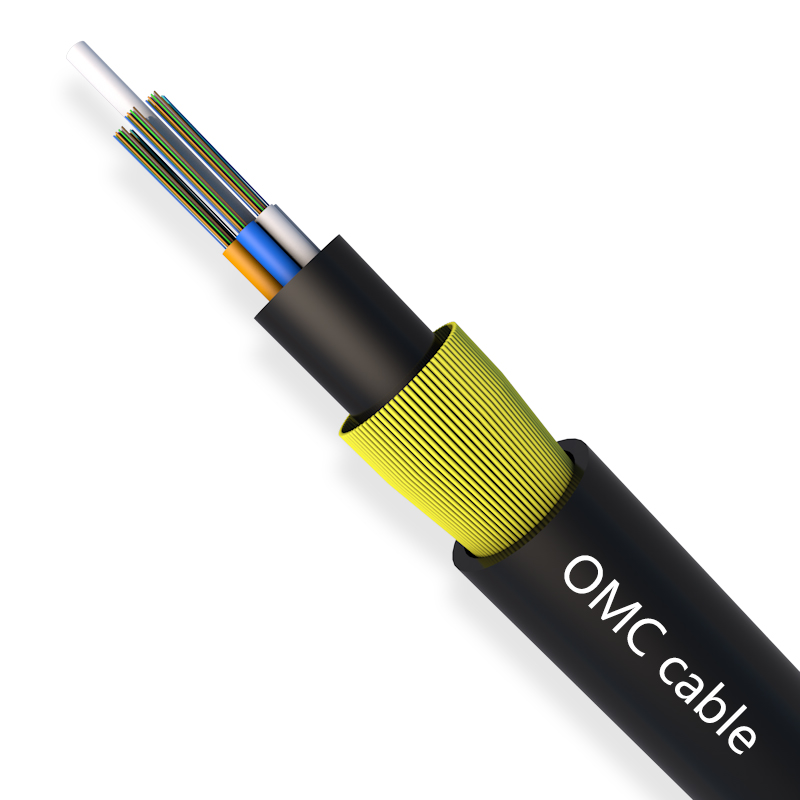

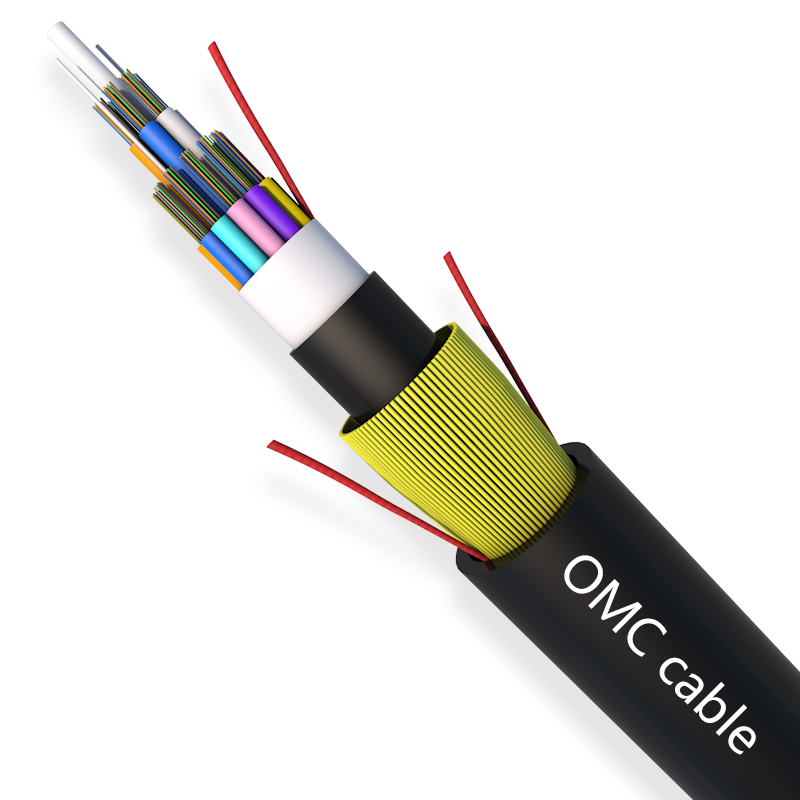

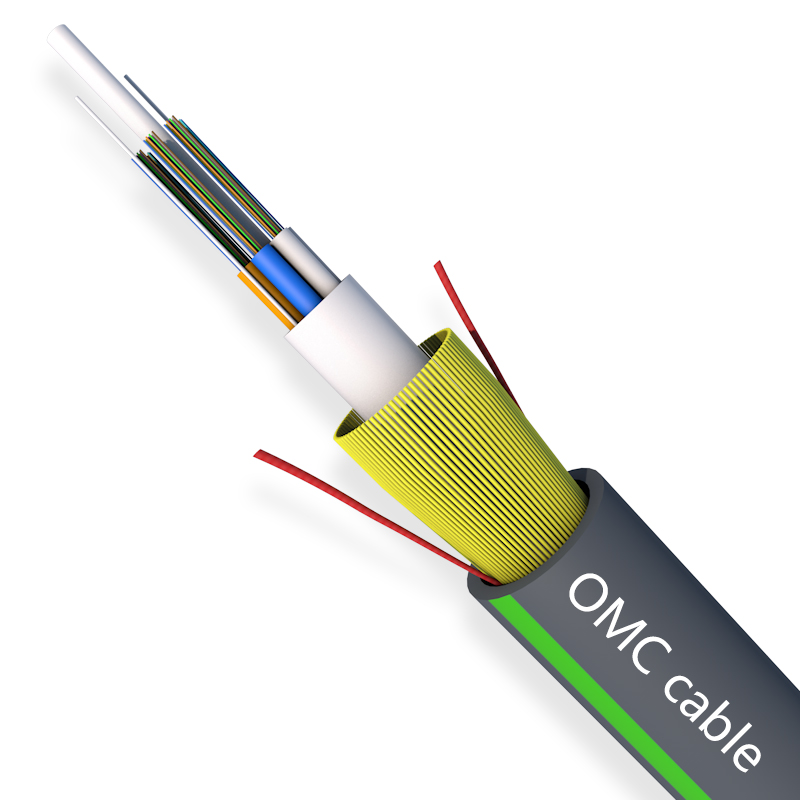

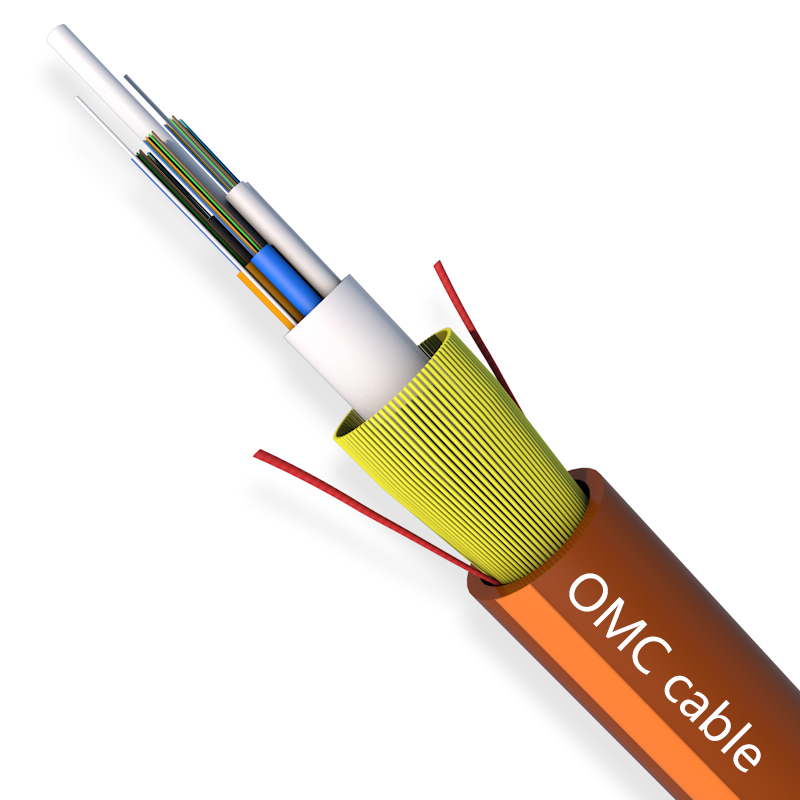

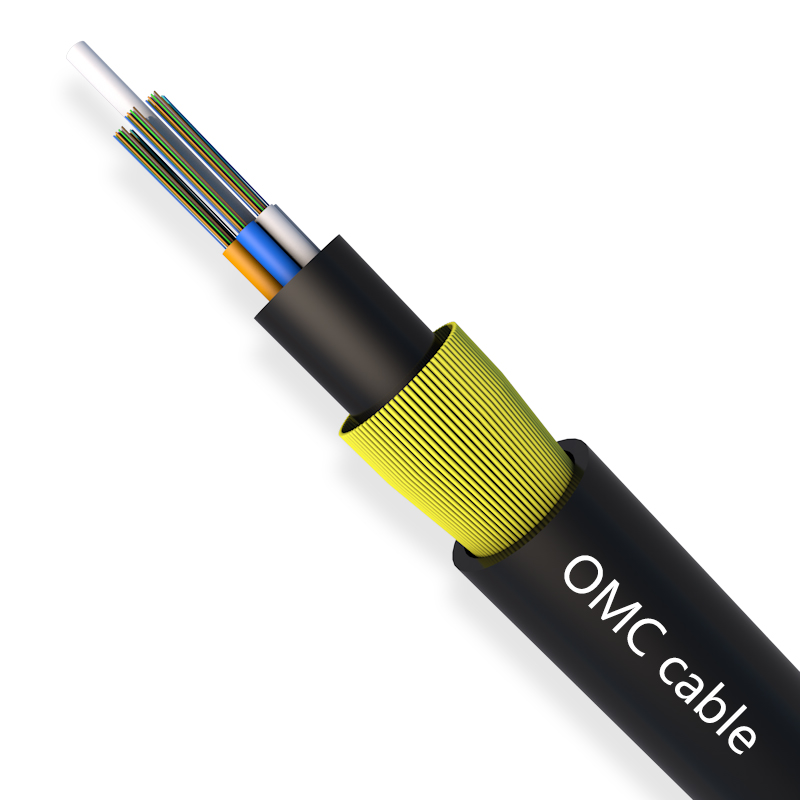

OMC ADSS (All-Dielectric Self-Supporting) fiber optic cable is a specially designed cable for aerial applications. Unlike traditional fiber optic cables, ADSS cable does not require metallic components, making it fully non-conductive and ideal for installation in high-voltage environments. Its robust design enables it to withstand extreme weather conditions, offering reliable performance over long distances without additional support structures.

Advantages of ADSS Fiber Optic Cable

At OMC Cable, we specialize in providing high-quality ADSS fiber optic cable tailored to various environmental and installation requirements. With years of experience, cutting-edge manufacturing technology, and strict quality control, we ensure our ADSS cable meets industry standards for performance and durability. Our team provides expert consultation to help clients select the best cable ADSS solutions for their specific needs.

Strong and Durable

The ADSS fiber optic cable is designed to resist environmental factors such as wind, ice, and UV radiation, ensuring long service life and minimal maintenance.

Lightweight and Flexible

With its all-dielectric construction, cable ADSS is lighter than conventional cables, making installation easier and reducing overall infrastructure costs.

High Tensile Strength

The cable’s advanced aramid yarn reinforcement provides excellent tensile strength, allowing long-span installations without the need for support structures.

Electrical Safety

As an all-dielectric cable, ADSS cable is safe for use in high-voltage areas, eliminating the risk of electrical interference and damage.

Cost-Effective

The self-supporting design reduces the need for additional hardware, making the cable an economical choice for fiber optic network deployments.

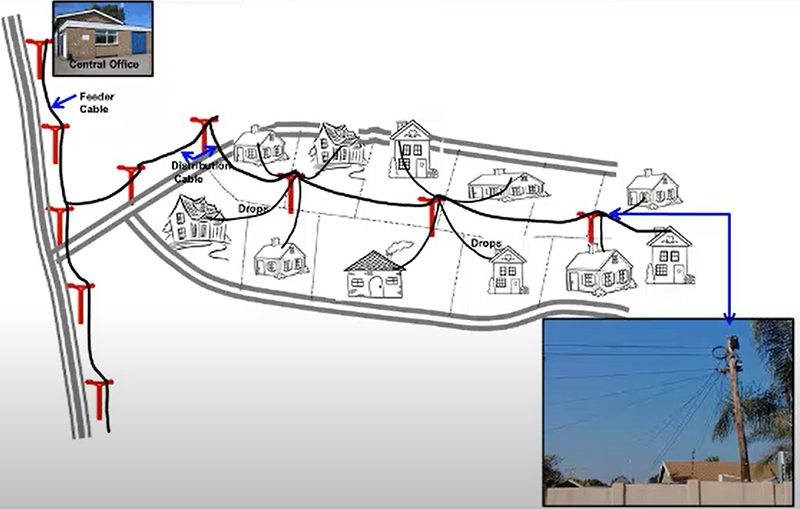

Application for ADSS Cable

ADSS fiber optic cable is widely used in:

Power Transmission Networks: Installed alongside power lines without risk of electrical interference.

Telecommunication Networks: Used for high-speed data transmission across long distances.

Rural and Remote Areas: Ideal for connecting areas where underground cabling is impractical.

Railway and Highway Communication: Ensures stable signal transmission along transportation routes.

Customization Options

We offer custom cable ADSS solutions to meet specific project requirements. Our customization process includes:

- Fiber Count Selection: Choose from 2 to 144 fibers.

- Outer Sheath Material: Select from PE or AT sheath for different environmental conditions.

- Span Length Design: Tailor the cable strength for spans from 100 to 1500 meters.

- Jacket Color and Marking: Customize the outer jacket color and print specifications.

- Packaging and Delivery: Choose between wooden or plastic reels with customized lengths.

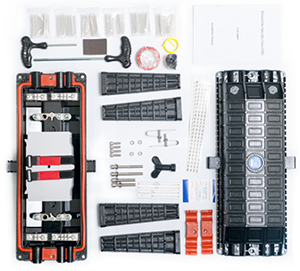

Recommended Products to Use with ADSS Cable

ADSS Tension Clamps

For securely anchoring the cable

ADSS Suspension Clamps

To support the cable and reduce stress.

Fiber Optic Splice Closures

To protect fiber splices from environmental factors.

FAQ

Q: What is the maximum span length of cable ADSS?

A: Depending on the design, ADSS cable can span distances of up to 1500 meters without support.

Q: Is ADSS cable affected by weather conditions?

A: No, ADSS fiber optic cable is designed to withstand extreme temperatures, wind loads, and UV exposure.

Q: Can cable ADSS be used near high-voltage power lines?

A: Yes, its all-dielectric structure makes it safe for installation in high-voltage environments.

Q: How is ADSS cable installed?

A: It is typically installed using tension clamps and suspension clamps, eliminating the need for messenger wires.

Q: What fiber counts are available for cable ADSS?

A: ADSS cable can be customized to include a wide range of fiber counts, from 2 to 144 fibers.

Q: What is the lifespan of ADSS cable?

A: With proper installation and maintenance, cable ADSS can last over 30 years.