Description

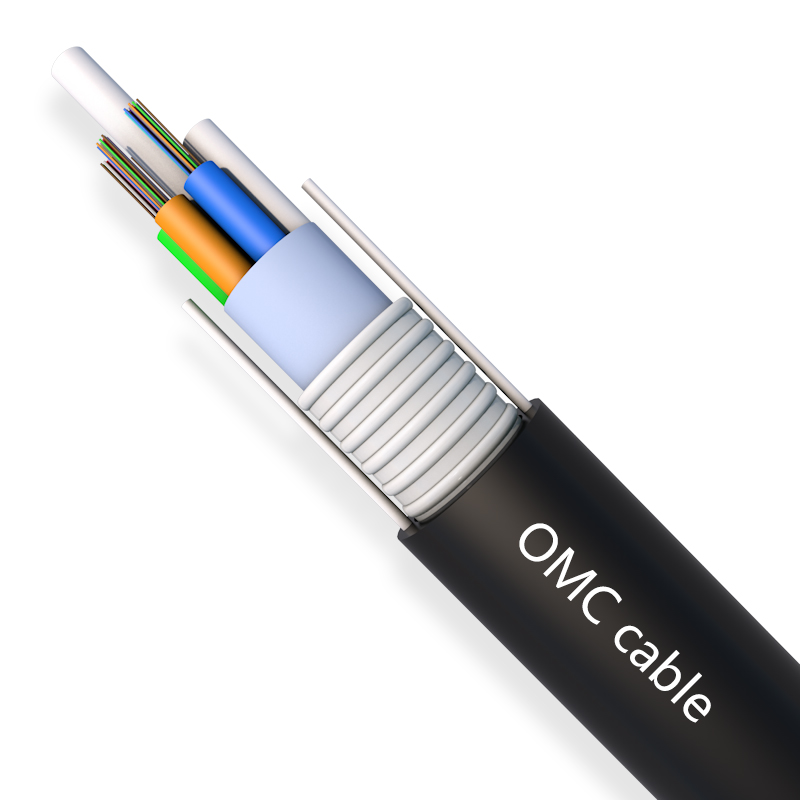

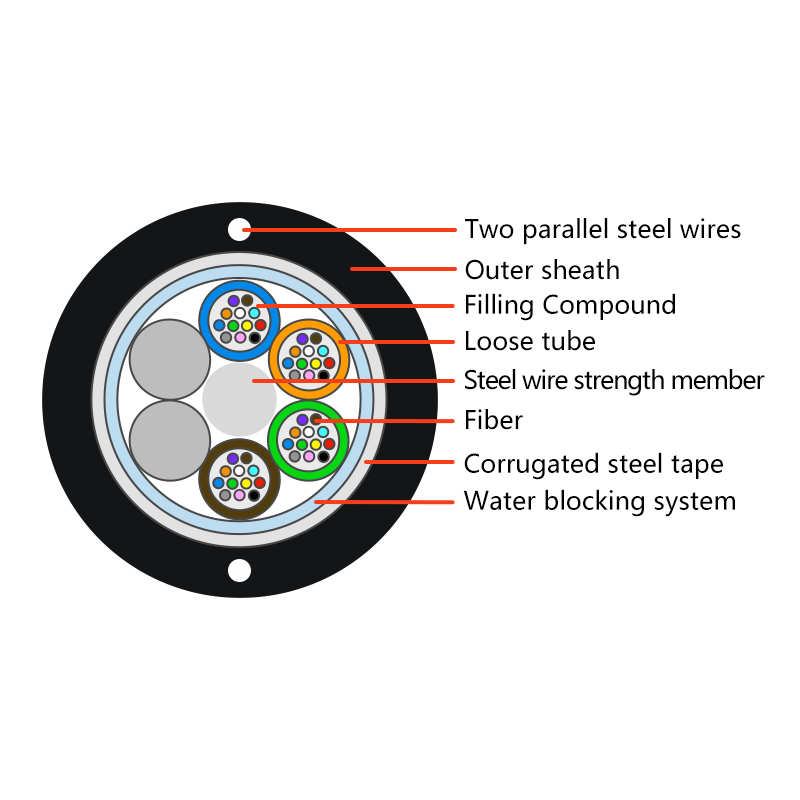

In OMC’s 8-32-64F Stranded Loose Tube Armored Cable –GYSTW, A steel wire is located in the center of core as a metallic strength member. Single-mode/multimode Fiber are positioned in the loose tube, which is made of PBT materials and filled with filling compound. The loose tube is covered with water blocking Yarn+Corrugated Steel tape. At the same time. Two parallel steel wires are embedded in PE out sheath to offer high tensile. The cable is completed with a PE sheath.

Standard color of fiber and tube

The color code of the individual fibers, shall be in accordance with the table as below

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Tube color code for 12~144 fibers:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Cable Structure parameter

| Fiber number | Tube number | Fiber per tube | Cable OD | Cable Weight | Fiber type |

| 8 | 5 | 8F/Tube | 11.6±0.5mm | 175±5kg/km | OS1,OS2,OM1,OM2, OM3,OM4 |

| 32 | 5 | 12F/Tube | 11.6±0.5mm | 175±5kg/km | |

| 64 | 6 | 12F/Tube | 13.60 ±0.5mm | 265±5kg/km |

Cable Material parameter

| Items | Description | |

| Moisture Barrier | Water blocking system | |

| Central strength member | Material | Steel wire |

| size | 1.4mm | |

| Loose tube | material | PBT |

| diameter | Ф2.0(outer/inner) | |

| Tube-filling | material | Tube filling compound |

| Armoring | Material | Corrugated steel tape |

| strength member | Material | Steel wire |

| size | 1.2 mm | |

| Outer sheath | material | PE/HDPE |

| diameter | 1.60±0.2mm | |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 1500N fiber strain≤0.6% |

| Long term | 600N | |

| Max. crush resistance | Short term | 1000N/100mm |

| Long term | 300N/100mm | |

| Min. bending radius | Installation | 20 x cable diameter |

| Operation | 10 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Optical fiber technical parameters

| Fiber style | Unit | SM 9/125 | MM 50/125 | MM 62.5/125 | |

| Condition | nm | 1310/1550 | 850/1300 | 850/1300 | |

| Attenuation | dB/km | ≤0.34/0.2 | ≤3.0/1.0 | ≤3.0/1.0 | |

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ….. | ….. |

| 1550nm | Ps/(nm*km) | ≤22 | ….. | ….. | |

| Bandwidth | 850nm | MHZ. KM | ….. | ≧400 | ≧160 |

| 1300nm | MHZ. KM | ….. | ≧800 | ≧500 | |

| Zero dispersion wavelength | nm | ≧1302,

≤1322 |

….. | ….. | |

| Zero dispersion slope | nm | ≤0.091 | ….. | ….. | |

| PMD Maximum Individual Fiber | ≤0.2 | ….. | ….. | ||

| PMD Design Link Value | Ps(nm2*km) | ≤0.08 | ….. | ….. | |

| Fiber cutoff wavelength λc | nm | ≧1180,

≤1330 |

….. | ….. | |

| Cable cutoff wavelength λcc | nm | ≤1260 | ….. | ….. | |

| MFD | 1310nm | um | 9.2±0.4 | ….. | ….. |

| 1550nm | um | 10.4±0.8 | ….. | ….. | |

| Numerical Aperture(NA) | …… | 0.200±0.015 | 0.275±0.015 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.08 | ≤0.10 | |

| Attenuation uniformity | dB/km | ≤0.01 | ……. | ……. | |

| Core diameter | um | …… | 50±1.0 | 62.5±2.5 | |

| Cladding diameter | um | 125.0±0.1 | 125.0±0.1 | 125.0±0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242±7 | 242±7 | 242±7 | |

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | |

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding concentricity error | um | ≤0.6 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ….. | ….. | |