Description

All-dielectric self-supporting cable (ADSS cable) is a type of fiber optic cable specifically engineered for aerial installation on power utility poles and transmission towers. Unlike conventional optical cables that may rely on metallic elements for strength or protection, ADSS contains no metallic components at all. This makes it lightweight, non-conductive, and resistant to electromagnetic interference. Its dielectric design allows it to be installed directly alongside high-voltage power lines without the risk of electrical hazards, which is why it has become a preferred choice for electric utilities and telecom operators worldwide.

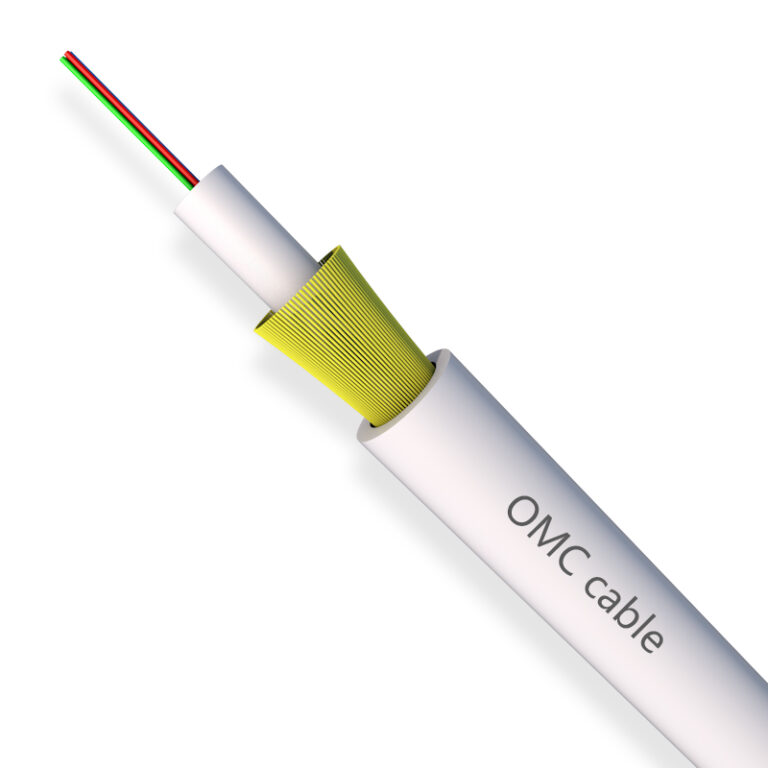

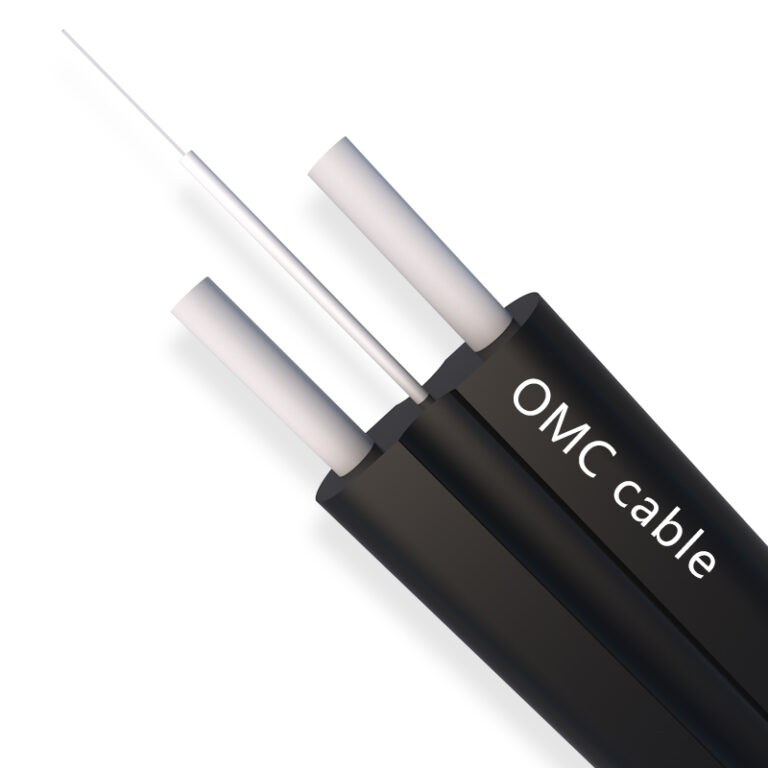

As a reliable fiber optic cable supplier, OMC can offer OMC can offer 4-432 cores ADSS cables with different Span length from 50m -1000m.

Features and Advantages

Non-metallic structure, good insulation, lightning protection

The aramid yarn has excellent production technology, uniform force, excellent stress-strain performance, excellent gunshot resistance and best anti-electric corrosion performance

No blackout construction, power line failure does not affect the normal transmission of optical cable

Smooth shape, so that the cable has superior aerodynamic performance

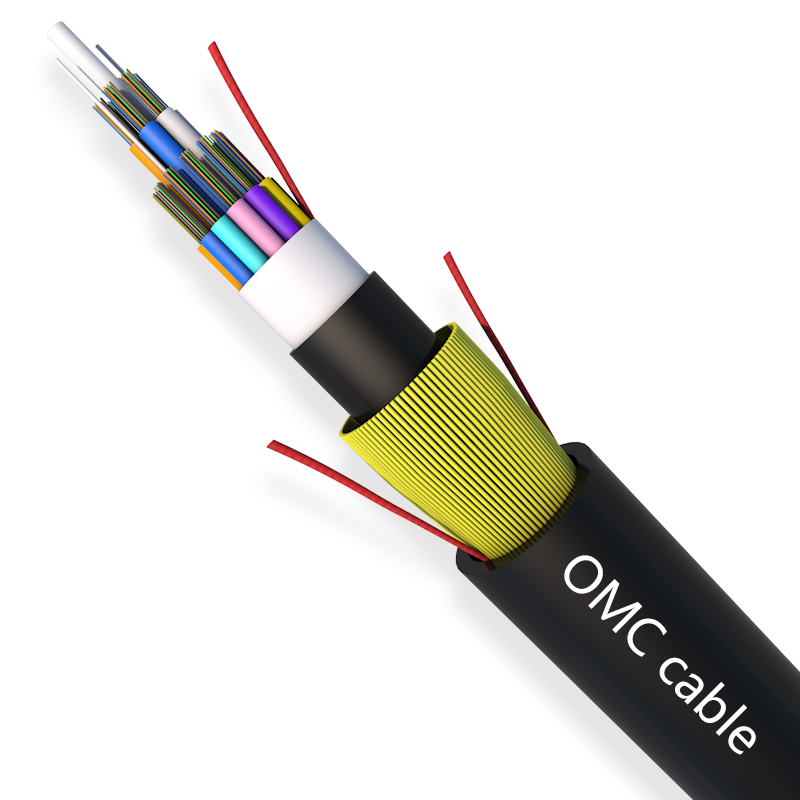

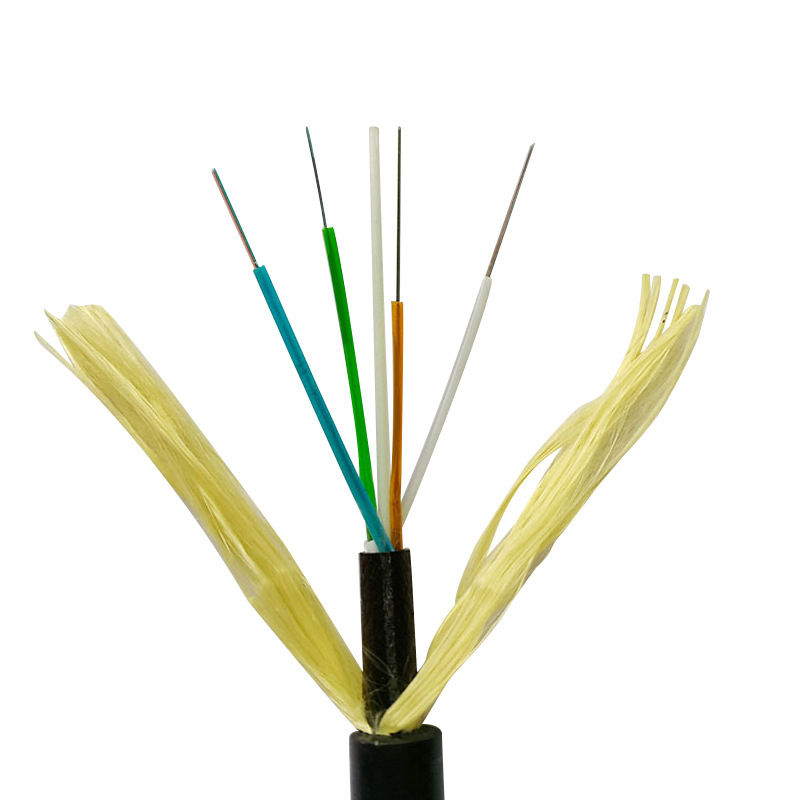

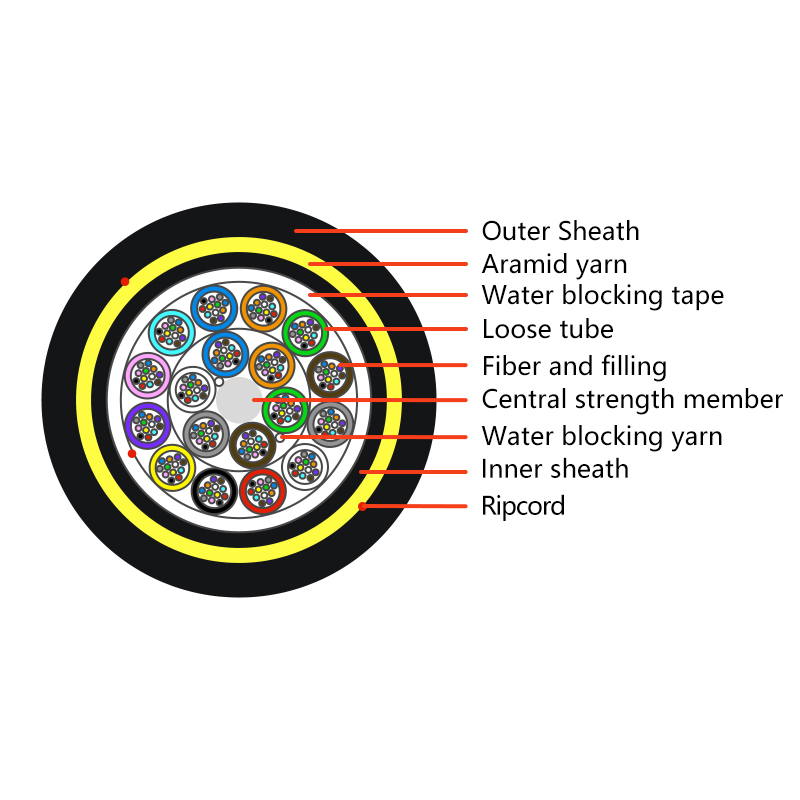

Cable structure

| Item | Contents | Unit | Value | ||||||||||

| Fiber count | Number | / | 4-8 | 12-72 | 96 | 144 | 288 | 432 | |||||

| Fiber type | / | / | G652D | ||||||||||

| Cable structure | / | / | 1+6 | 1+6 | 1+8 | 1+12 | 1+9+15 | 1+6+12 | |||||

| Fibers per tube | Count | / | 4-8 | 12 | 12 | 12 | 12 | 24 | |||||

| Fibers color | / | / | Blue、Orange、Green、Brown、Gray、White、Red、Black、Yellow、Violet、Pink、Aqua、Blue*、Orange*、Green*、Brown*、Gray*、White*、

Red*、Natural*、Yellow*、Violet*、Pink*、Aqua*,(*: Black dot marking) |

||||||||||

| Filler | Material | / | PP | ||||||||||

|

Loose tube |

Material | / | PBT | ||||||||||

| Nominal Diameter | mm | 2.2 | 2.8 | ||||||||||

| color | / | 4-144F:Blue、Orange、Green、Brown、Gray、White、Red、Black、Yellow、Violet、Pink、Aqua

288F:Blue、Orange、Green、Brown、Gray、White、Red、Black、Yellow、Violet、Pink、Aqua、Blue*、Orange*、Green*、Brown*、Gray*、White*、Red*、Nature*、Yellow*、Violet*、Pink*、Aqua*(* : Stripe (color : black)) 432F:Blue、Orange、Green、Brown、Gray、White、Red、Black、Yellow、Violet、Pink、Aqua、Blue*、Orange*、Green*、Brown*、 Gray*、White*(* : Stripe (color : black)) |

|||||||||||

| Central strength member | Material | / | FRP &PE cushion layer (when need) | ||||||||||

| Nominal Diameter | mm | 2.4 | 2.4 | 3.0 | 3.0 | 3.0 | 2.8 | ||||||

| PE cushion layer | mm | – | – | 3.8±0.2 | 6.7±0.2 | 4.2±0.2 | – | ||||||

| Water blocking | Material | Water blocking tape | |||||||||||

| Peripheral strength

member |

Material | Aramid yarn | |||||||||||

| Ripcord | Number | 3 | |||||||||||

| Inner sheath | Material | HDPE | |||||||||||

| Color | Black | ||||||||||||

| Outer sheath | Material | HDPE | |||||||||||

| Color | Black | ||||||||||||

| Thickness(mm) | Nom:2.0 | ||||||||||||

| Attenuation

(after cable) |

1310nm | dB/km | £0.36 | ||||||||||

| 1550nm | dB/km | £0.22 | |||||||||||

| Cable diameter | ±5% | mm | 13.0 | 13.1 | 14.5 | 17.5 | 20.3 | 20.9 | |||||

| Cable weight | ±10% | kg/km | 130 | 135 | 167 | 238 | 314 | 329 | |||||

| Sag | / | % | 1 | ||||||||||

| icing-thickness | / | mm | 5mm | ||||||||||

| wind speed | / | m/s | 2.8m/s (Max 34m/s) | ||||||||||

Standard color of fiber and tube

The color code of the tubes and the individual fibers, shall be in accordance with the table as below:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Slate | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 5500N(Fiber strain≤0.33%) |

| Max. crush resistance | Short term | 3000 N/100mm |

| Min. bending radius | Installation | 20x cable diameter |

| Operation | 10 x cable diameter | |

|

Temperature range |

Operation | -40℃ ~ +70℃ |

| Installation | -40℃ ~ +55℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Optical fiber technical parameters-SMF

| Item | Unit | Specification | |

| G. 652D | |||

| Mode field diameter | 1310nm | mm | 9.2 ± 0.4 |

| 1550nm | mm | 10.4 ± 0.5 | |

| Cladding diameter | mm | 125.0 ± 0.7 | |

| Cladding non-circularity | % | £1.0 | |

| Core concentricity error | mm | £0.6 | |

| Coating diameter | mm | 242 ± 7 | |

| Coating/cladding concentricity error | mm | £12 | |

| Cable cut-off wavelength λcc | nm | £ 1260 | |

| Attenuation | 1310nm | dB/km | £0.35 |

| 1550nm | dB/km | £0.21 | |