Description

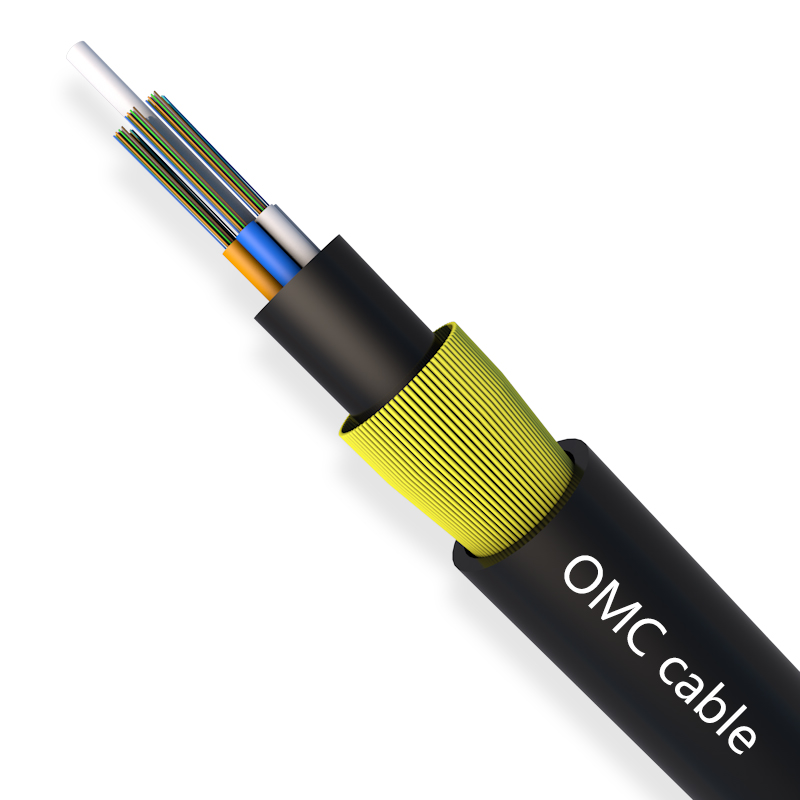

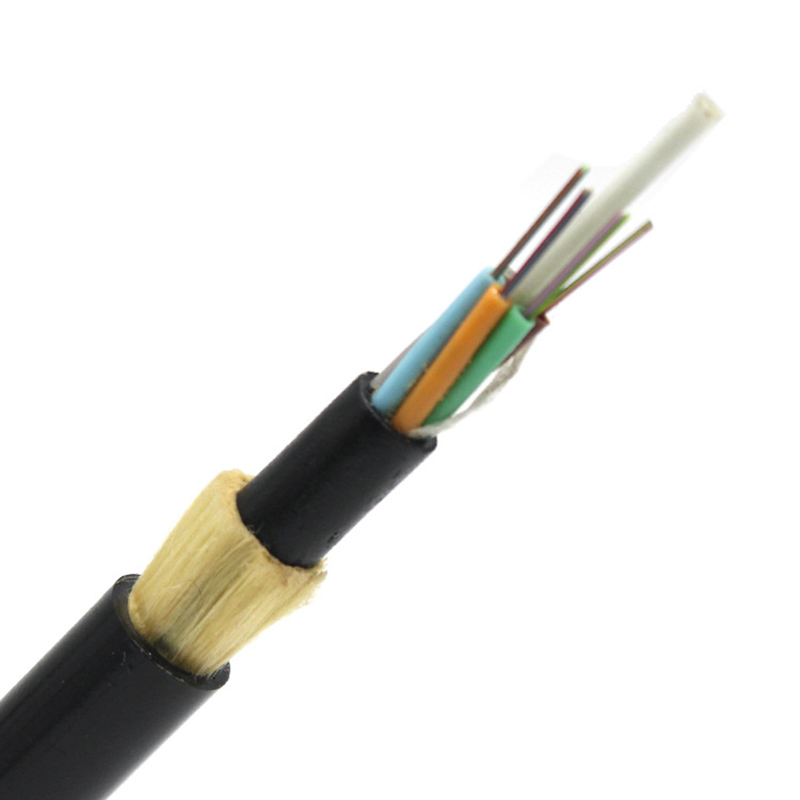

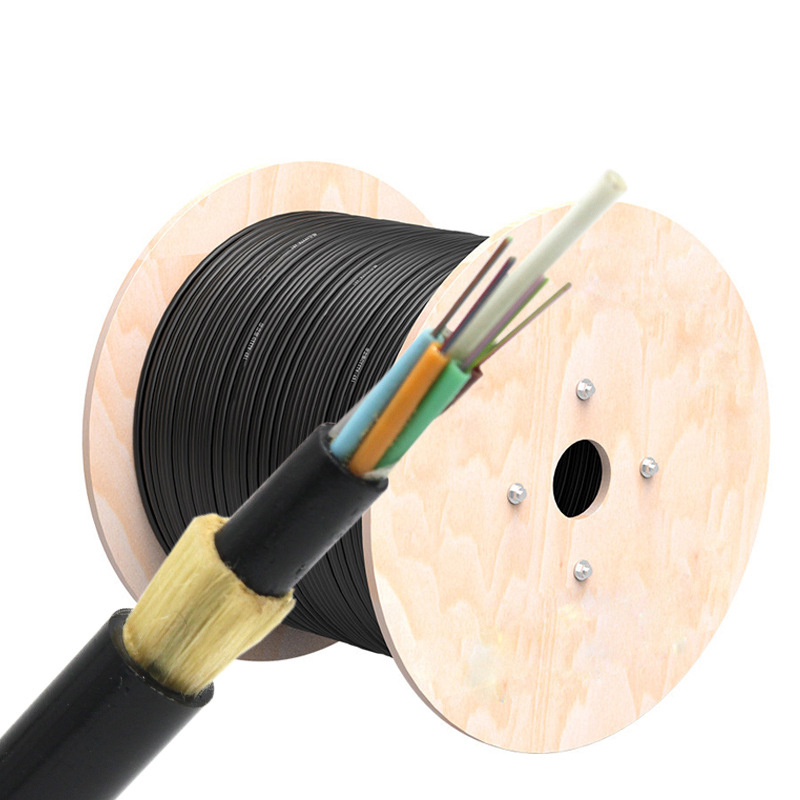

OMC’s 96cores ADSS cable is Used Double sheath cable structure,1+8 tubes cable body to build this good performance outdoor aerial installation cable.

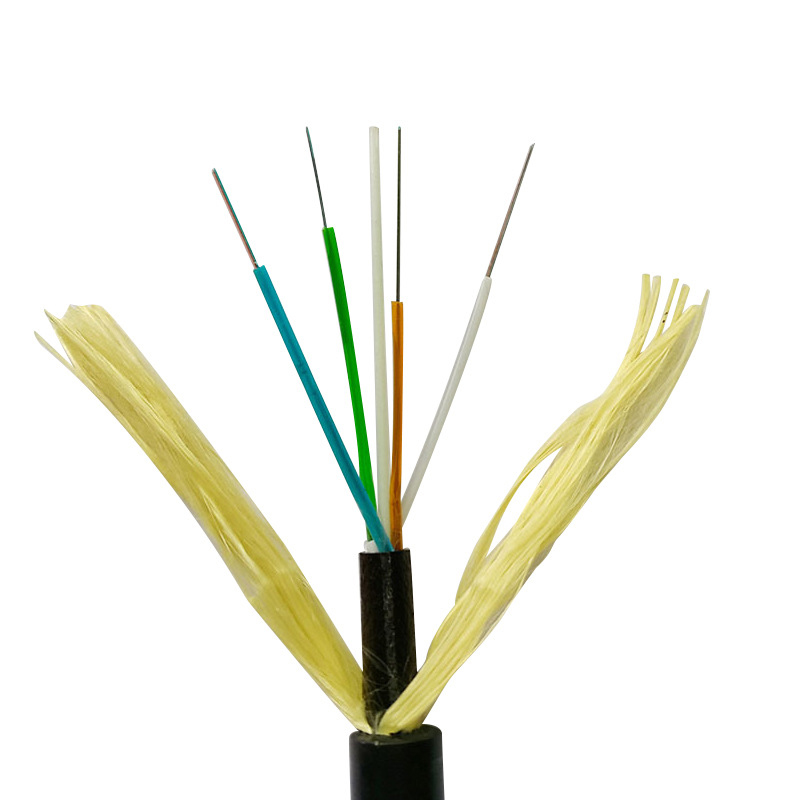

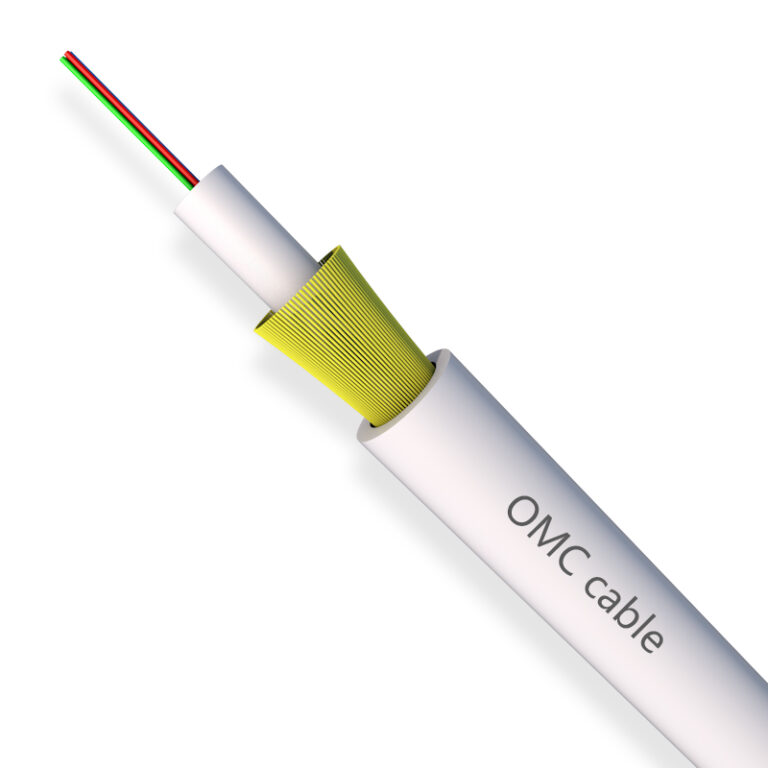

ADSS structure of the optical cables adopts loose tube twisted structure. 250 um optical fibers are inserted into loose tube made of high modulus polyester and filled with non-metallic reinforcing members (FRP) around the center of the cable to form a round core. The gap in the core is filled with water-blocking ointment, Two layers of Aramid yarn are twisted to reinforce the yarn, Finally, polyethylene (PE) sheath is extruded.

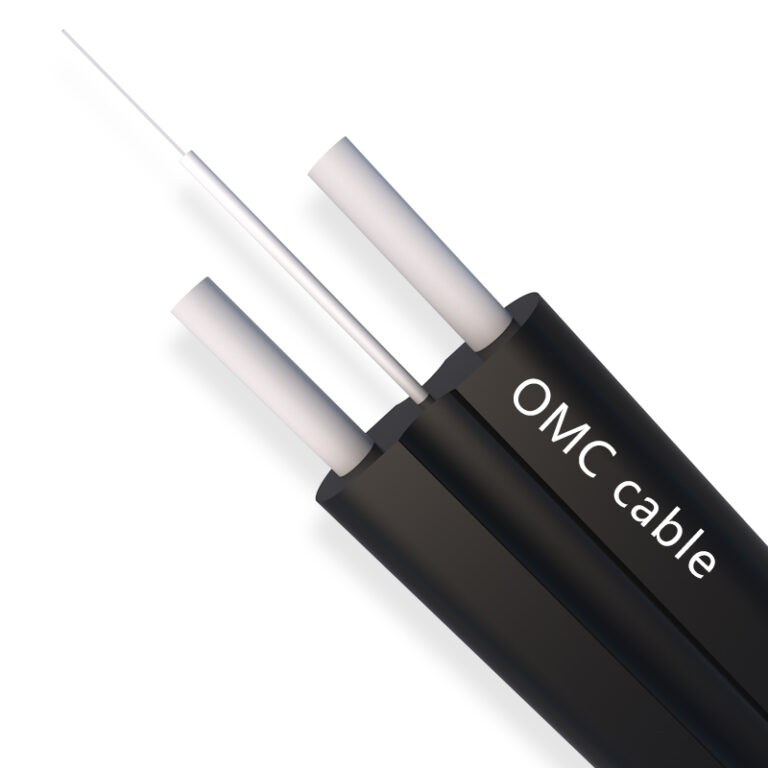

These ADSS cables offer reliable self-support performance for distances up to 50m. As its name indicates, there is no support or messenger wire required, so installation is achieved in a single pass, making ADSS an economical and simple means of building a fiber optic network.

Features and Advantages

Non-metallic structure, good insulation, lightning protection

The aramid yarn has excellent production technology, uniform force, excellent stress-strain performance, excellent gunshot resistance and best anti-electric corrosion performance

No blackout construction, power line failure does not affect the normal transmission of optical cable

Smooth shape, so that the cable has superior aerodynamic performance

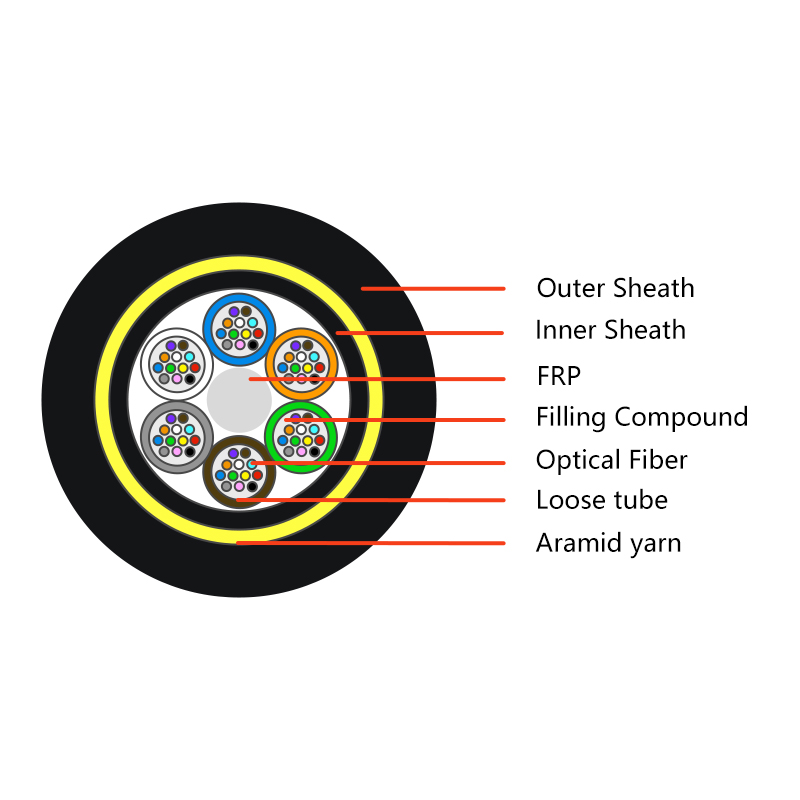

Cable structure

| Item | Contents | Unit | Value | |

| Fiber count | Number | / | 64 | 96 |

| Fiber type | / | / | G652D | |

| Cable structure | / | / | 1+8 | 1+12 |

| Fibers per tube | Count | / | 8 | |

|

Loose tube |

Material | / | PBT | |

| Nominal Diameter | mm | 2.2 | ||

| Color | / | Blue、Orange、Green、Brown、Gray、White、Red、

Black、Yellow、Violet、Pink、Aqua |

||

|

Central strength member |

Material | / | FRP &PE cushion layer | |

| Nominal Diameter | mm | 2.4/3.8 | 2.6/6.6 | |

| Water blocking | Material | / | Water blocking yarn & tape | |

| Peripheral strength member | Material | / | Aramid yarn | |

|

Inner sheath |

Material | / | MDPE | |

| Color | / | Black | ||

| Average Thickness | mm | 0.7 | ||

|

Outer sheath |

Material | / | MDPE | |

| Color | / | Black | ||

| Average Thickness | mm | 1.6 | ||

|

Attenuation (After cable) |

1310nm | dB/km | £0.36 | |

| 1550nm | dB/km | £0.22 | ||

| Cable diameter | ±5% | mm | 13.3 | 16.1 |

| Cable weight | ±7% | kg/km | 135 | 197 |

| Suitable span | / | m | 50 | |

| Sag | / | % | 1 | |

| Icing-thickness | / | mm | 0 | |

| Wind speed | / | m/s | 25 | |

Standard color of fiber and tube

The color code of the tubes and the individual fibers, shall be in accordance with the table as below:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Slate | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load (64 core) | Max allowable tension | 2000N (fiber strain≤0.33%) |

| Max. tensile load (96 core) | Max allowable tension | 2300N (fiber strain≤0.33%) |

|

Max. crush resistance |

Short term | 2200 N/100mm |

| Long term | 700N | |

|

Min. bending radius |

Installation | 25 x cable diameter |

| Operation | 15 x cable diameter | |

|

Temperature range |

Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Optical fiber technical parameters-SMF

| Item | Unit | Specification | |

| G. 652D | |||

| Mode field diameter | 1310nm | mm | 9.2 ± 0.4 |

| 1550nm | mm | 10.4 ± 0.5 | |

| Cladding diameter | mm | 125.0 ± 0.7 | |

| Cladding non-circularity | % | £1.0 | |

| Core concentricity error | mm | £0.6 | |

| Coating diameter | mm | 242 ± 7 | |

| Coating/cladding concentricity error | mm | £12 | |

| Cable cut-off wavelength λcc | nm | £ 1260 | |

| Attenuation | 1310nm | dB/km | £0.35 |

| 1550nm | dB/km | £0.21 | |