Description

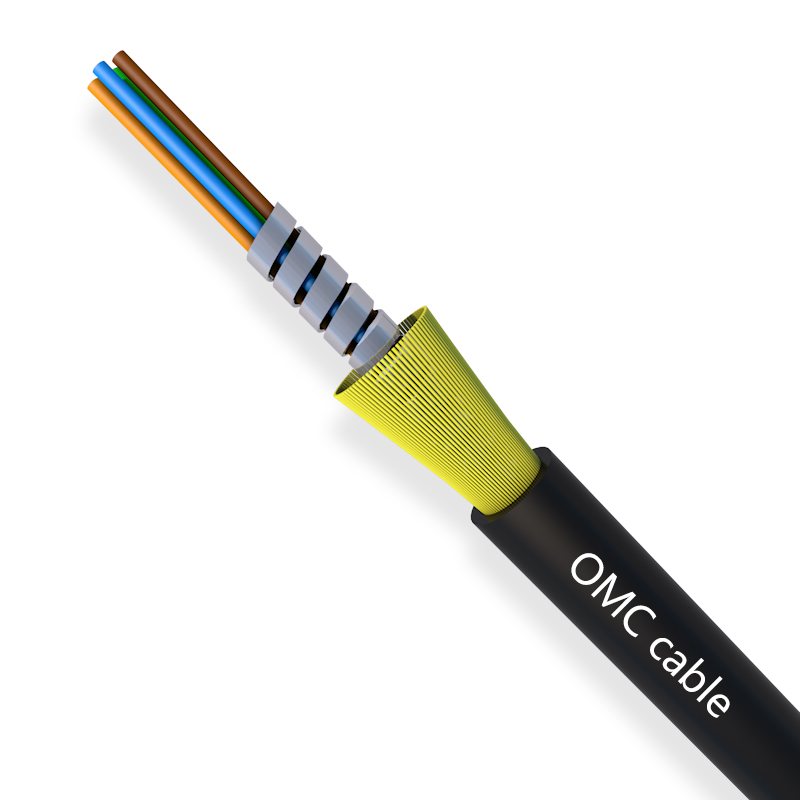

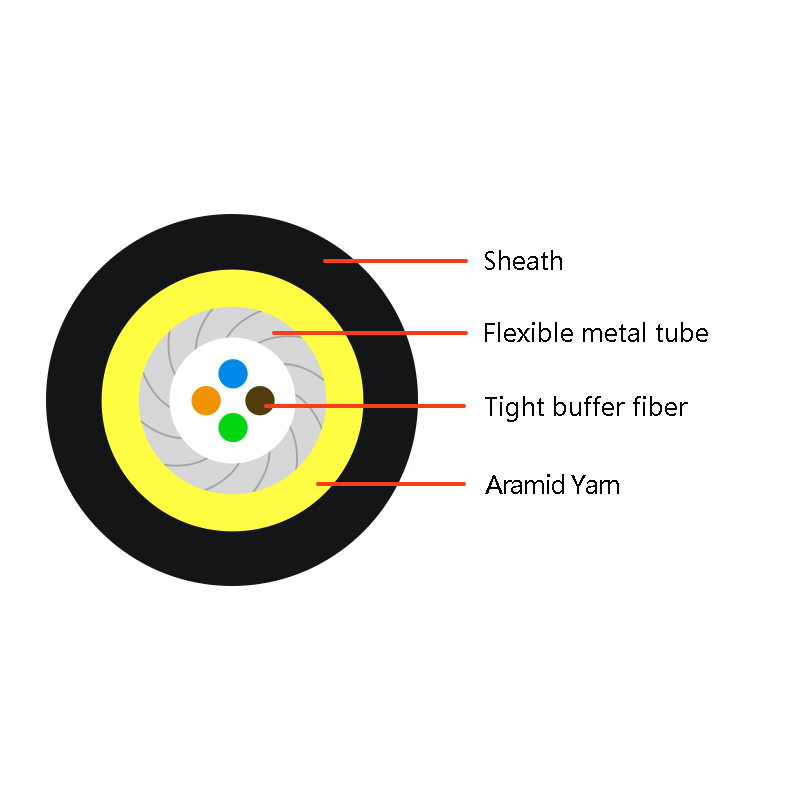

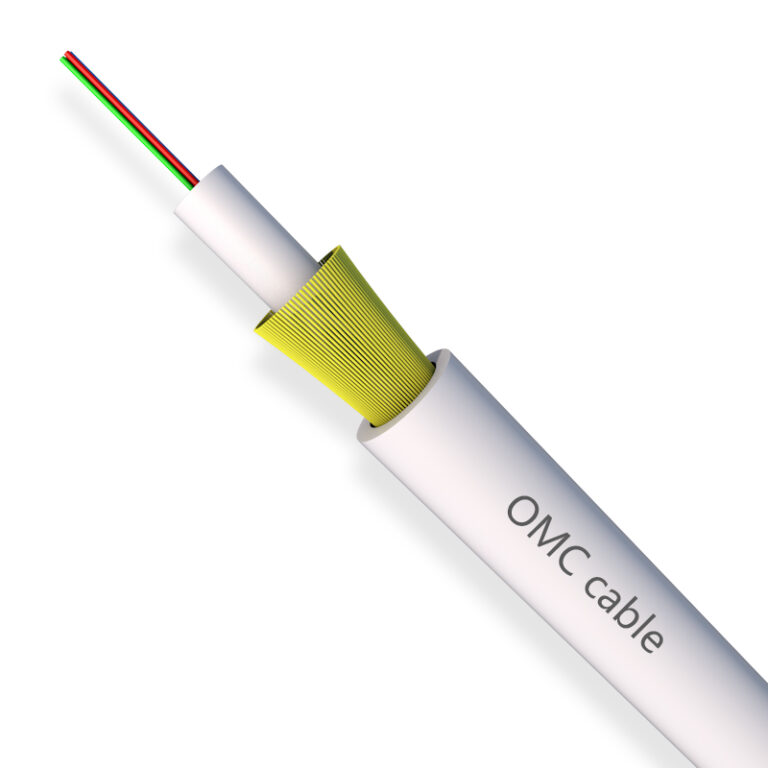

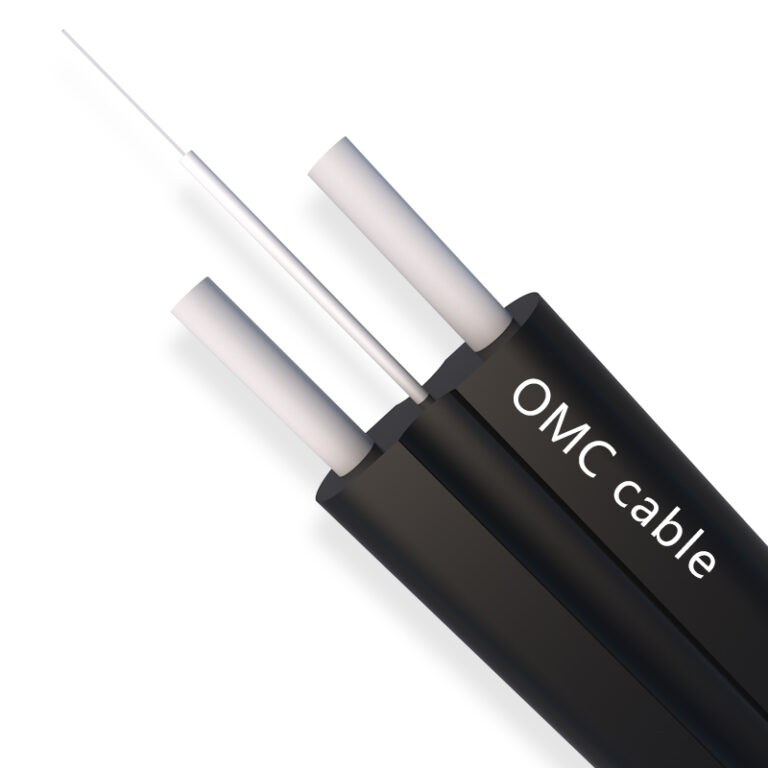

4F 7.0mm CPRI Armored cable is an armored type CPRI cable with a cable OD of 7.0mm for FTTA projects. The fiber channels of this cable are 4x 900um tight buffer cables. A spiral steel tube covers those tight buffer cables to offer high protection. An aramid yarn covers the steel tube as a strength member. CPRI cables establish a reliable, highspeed connection between remote radio heads and base stations. These cables link the remote radio head to the base station’s CPRI interface, enabling the seamless transfer of data at exceptional speeds.

Features:

- High anti-tensility; High anti-pressure

- High bent Resistance; Anti-bite from rodent animals

- Small OD stainless steel protection tube

- Don’t worry about damage in project

- The flexible metal tube steel tape functions as protection as well as reinforcing the crush.USE as normal soft cable.

- Resistance and mechanical performance.

- The jacket possesses good ultra violet radiation resistant property.

Products detail:

| Item | Contents | Unit | Value |

| Optical Fiber | Model number | / | G657A1/G657A2/OM2/OM3/OM4 |

| number | / | 4 | |

| Color | / | nature | |

| Sub cable | color | / | Blue, orange,green,brown |

| material | / | LSZH or PVC | |

| diameter | mm | 0.9±0.05 | |

| Strength member | Material | 1 | Aramid Yarn |

| Material | 2 | SUS204 Stainless steel tube diameter

(Φ4.7±0.05mm) |

|

| Outer jacket | Diameter | mm | 7.0±0.2 |

| Material | / | LSZH | |

| Color | / | black | |

| Cable attenuation | dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm | |

| Cable weight (Approx.) | kg/km | 21.4 | |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Tensile load | Short term | 800N fiber strain≤0.33% |

| Long term | 400N | |

| Crush resistance | Short term | 4500 |

| Long term | 2500 | |

| Min. bending radius | Installation | 25 x cable diameter |

| Operation | 12.5 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Application:

- Military telecommunication

- Coal, oil, natural gas, geological exploration and communication

- Broadcast television, temporary communication system

- FTTA Project

Optical fiber technical parameters-SM

| Parameter | Conditions | Units | Value | |||

| G652D | G657A1 | G657A2 | G657B3 | |||

| Optical Specification | ||||||

| Attenuation | 1310 nm | dB/km | ≤0.350 | ≤0.350 | ≤0.350 | ≤0.350 |

| 1383 nm | dB/km | ≤0.330 | ≤0.350 | ≤0.350 | ≤0.350 | |

| 1550 nm | dB/km | ≤0.210 | ≤0.210 | ≤0.210 | ≤0.210 | |

| 1625 nm | dB/km | ≤0.240 | ≤0.230 | ≤0.230 | ≤0.230 | |

| Attenuation vs. Wavelength | 1310 nm VS. 1285-1330 nm | dB/km | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.03 |

| 1550 nm VS. 1525-1575 nm | dB/km | ≤0.03 | ≤0.03 | ≤0.04 | ≤0.02 | |

| 1550 nm VS. 1480-1580 nm | dB/km | ≤0.04 | – | – | – | |

| Zero Dispersion Wavelength | \ | nm | 1300-1324 | 1300-1324 | 1300-1324 | 1300-1324 |

| Zero Dispersion Slope | ps/(nm2·km) | 0.073-0.092 | 0.073-0.092 | 0.073-0.092 | ≤0.092 | |

| Dispersion | 1550 nm | ps/(nm·km) | 13.3-18.6 | 13.3-18.6 | 13.3-18.6 | |

| 1625 nm | ps/(nm·km) | 17.2-23.7 | 17.2-23.7 | 17.2-23.7 | ||

| Polarization Mode Dispersion (PMD) | ps/√km | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

| Cut-off Wavelength λcc | – | nm | ≤1260 | ≤1260 | ≤1260 | ≤1260 |

| Mode Field Diameter (MFD) | 1310 nm | μm | 9.2±0.4 | 9.2±0.4 | 8.6±0.4 | 8.6±0.4 |

| 1550 nm | μm | 10.4±0.5 | 10.4±0.5 | 9.6±0.5 | 9.6±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 |

| 1550 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Bidirectional Attenuation | 1310 nm | dB/km | ≤0.04 | ≤0.05 | ||

| 1550 nm | dB/km | ≤0.04 | ≤0.05 | |||

| Geometrical | ||||||

| Cladding Diameter | μm | 125±0.7 | 125±0.7 | 125±0.7 | 125±0.7 | |

| Cladding Non-Circularity | % | ≤1.0 | ≤1.0 | ≤0.8 | ≤0.7 | |

| Core/Cladding Concentricity Error | μm | ≤0.6 | ≤0.5 | ≤0.5 | ≤0.5 | |

| Coating Diameter (Uncolored) | μm | 242±7 (standard) | ||||

| μm | 200±10 (optional) | |||||

| Coating/Cladding Concentricity Error | μm | ≤12 | ≤12 | ≤12 | ≤12 | |

| Curl | m | ≥4 | ≥4 | ≥4 | ≥4 | |

| Environmental (1550nm, 1625nm) | ||||||

| Temperature Cycling | -60℃ to +85℃ | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature &

High Humidity |

85℃, 85% RH, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Water Immersion | 23℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature Aging | 85℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

Optical fiber technical parameters-MM

| Features | Conditions | unit | Value | ||||

| OM1 | OM2 | OM2+ | OM3 | OM4 | |||

| Optical Characteristics | |||||||

| Attenuation | 850nm | dB/km | ≤2.70~≤3.00 | ≤2.50 | ≤2.50 | ≤2.50 | ≤2.50 |

| 1300nm | dB/km | ≤0.60~≤1.00 | ≤0.70 | ≤0.70 | ≤0.70 | ≤0.70 | |

| Minimum Modal Bandwidth | 850nm | MHz.km | ≥200~≥100 | ≥500~≥200 | – | – | – |

| 1300nm | MHz.km | ≥600~≥160 | ≥1200~≥400 | – | – | – | |

| Overfilled Launch Bandwidth | 850nm | MHz.km | – | – | ≥700 | ≥1500 | ≥3500 |

| 1300nm | MHz.km | – | – | ≥500 | ≥500 | ≥500 | |

| Effective Modal Bandwidth | 850nm | MHz.km | – | – | ≥950 | ≥2000 | ≥4700 |

| Numerical Aperture | 0.275±0.015 | 0.18~0.215 | |||||

| 10Gb/s Ethernet link length | M | – | – | 150 | 300 | 550 | |

| Backscatter Characteristics(1300nm) | |||||||

| Irregularities over fiber length and point discontinuity | dB | ≤0.1 | |||||

| Attenuation uniformity | dB | ≤0.1 | |||||

| Step (Mean of bidirectional(measurement) | dB/km | ≤0.1 | |||||

| Geometry Characteristics | |||||||

| Core Diameter | μm | 62.5±2.5 | 50±2.5 | ||||

| Core non-circularity | % | ≤5.0 | |||||

| Cladding Diameter | μm | 124.3±0.7 | |||||

| Cladding non-circularity | % | ≤2.0 | |||||

| Core/Cladding Concentricity Error | μm | ≤1.5 | |||||

| Coating Diameter | μm | 245±10 | |||||

| Coating/Cladding Concentricity Error | μm | ≤12.0 | |||||

| Delivery Length | km/reel | ~16.8 | |||||

| Environmental characteristics(850nm &1300nm) | |||||||

| Temperature dependence induced attenuation | -60℃~+85℃ | dB/km | ≤0.10 | ||||

| Temperature-humidity cycling deduced attenuation | -10℃~+85℃,98%RH | dB/km | ≤0.10 | ||||

| Water soak dependence induced attenuation | 23℃±2℃,30 days | dB/km | ≤0.10 | ||||

| Damp heat dependence induced attenuation | 85℃±2℃and85%RH,30 days | dB/km | ≤0.10 | ||||

| Dry heat aging | 85℃±2℃ | dB/km | ≤0.10 | ||||

Test Methods

| Test | Conditions | Acceptance criteria |

| Tensile strength IEC 60794-1-2 E1 | Tensile load: see Point 3 Sample length: ≥ 50 m Test duration: 1 min | – Fiber strain ≤0.6%

– No damage to outer jacket and inner elements |

| Crush resistance IEC 60794-1-2 E3 | Crush: see Point 3 Test duration: 5 min

Number of tests: 3 |

– Additional attenuation: ≤0.1dB after test

– No damage to outer jacket and inner elements |

| Impact

IEC 60794-1-2 E4 |

Impact Energy: 1J R=300 mm

Impact points: 3 Impact number: 1 |

– No obvious additional attenuation

– No damage |

| Repeated bending IEC 60794-1-2-E11A | Bending radius: 15x cable dia. Turn number: 4

Cycles: 3 |

– No obvious additional attenuation

– No damage |

| Torsion

IEC 60794-1-2 E7 |

Sample length: 2 m: Angles: ± 180°

Cycles: 10 |

– No obvious additional attenuation

– No damage |

| Temperature cycling IEC 60794-1-2 F1 | Steps: -30°C~+60°C

12 hours Cycles: 2 |

– Δα ≤ 0.15 dB/km

– Attenuation reversible – No damage |

| Water penetration IEC 60794-1-2 F5 | Sample length: 3 m

Water column height: 1 m Duration: 24 h |

– No water leak through the open end in 24 h |

| Filling compound flow

IEC 60794-1-2-E14 |

Sample length: 0.2 m 60°C

Duration: 24 h |

– No compound flow from the cable in 24 h |