Description

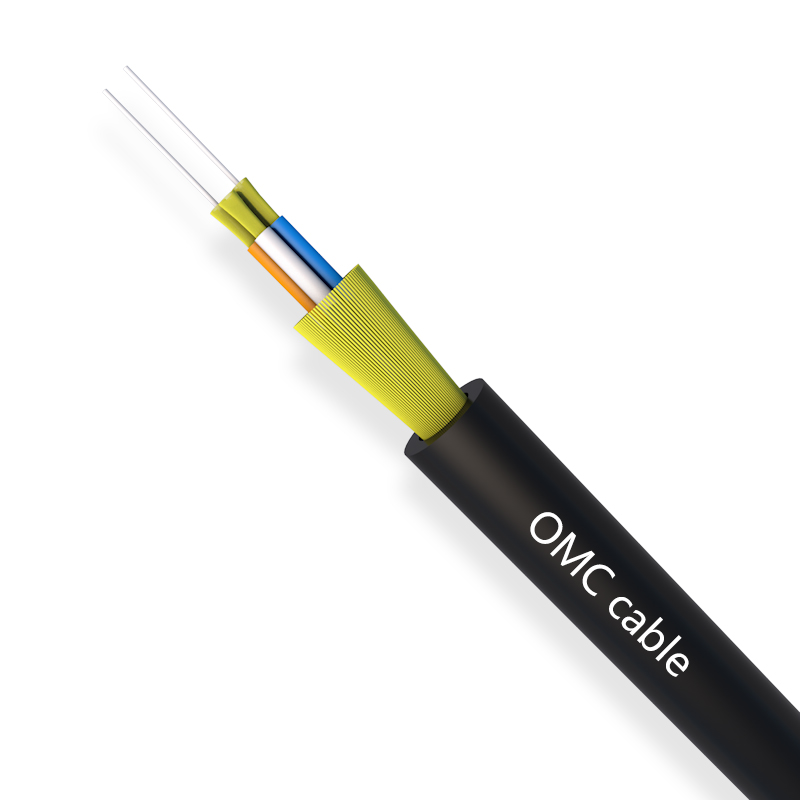

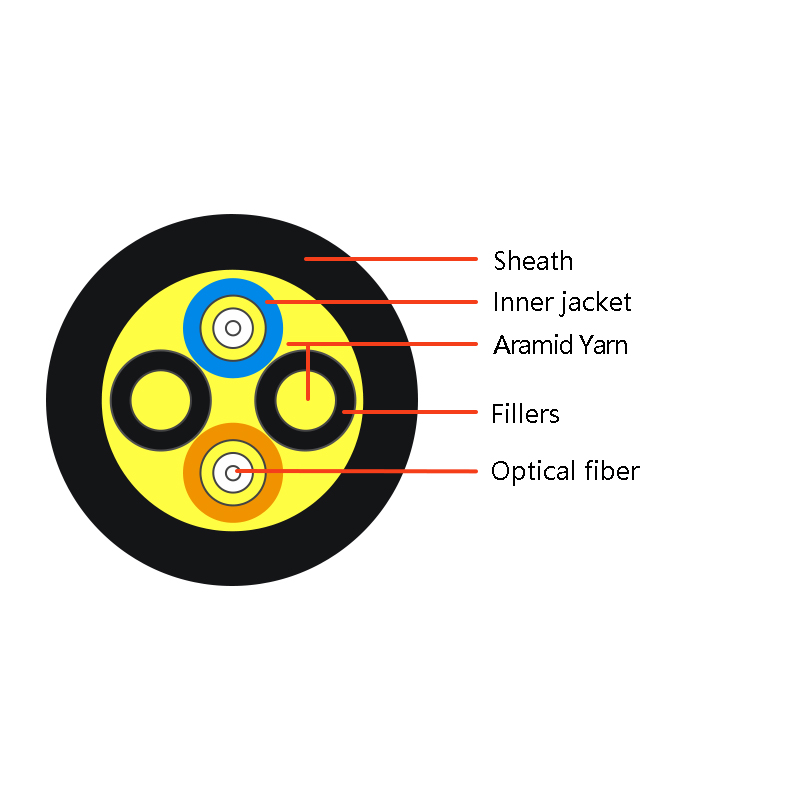

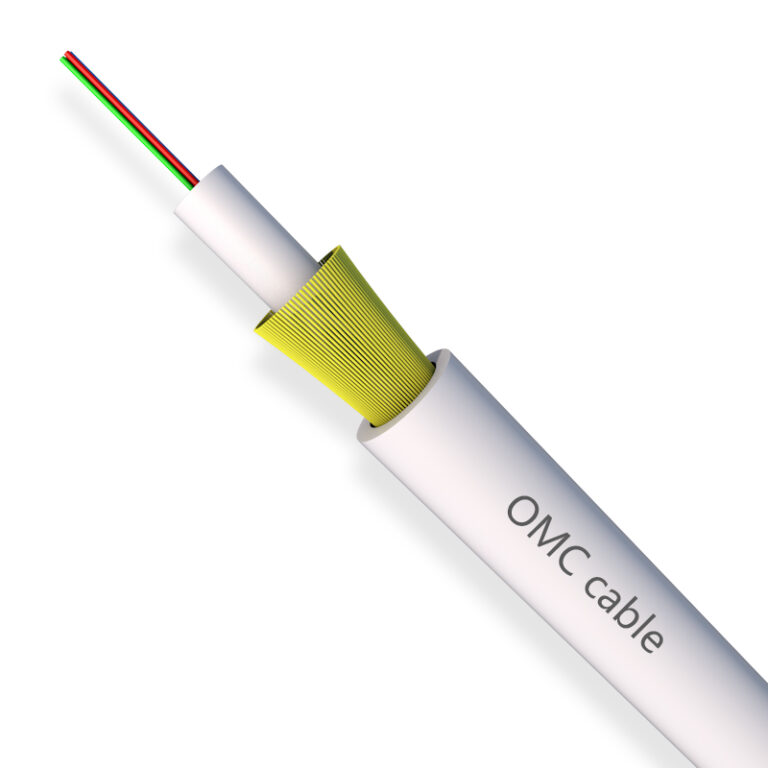

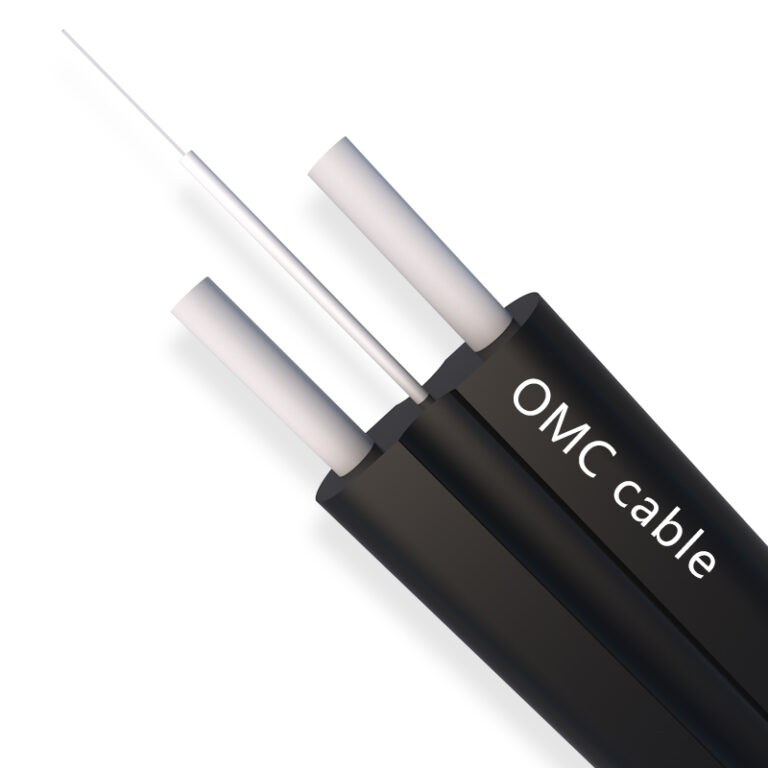

2F 7.0mm FTTA CPRI No-armored cable is a soft unarmored type CPRI cable with a cable OD of 7.0mm. There are 2 pieces of 2.0mm subunit cables and 2 pieces of fillers in it. A layer of aramid yarn covers the 4 subunit cables. Finally, an LSZH material sheath covers all units to form the final cable.

Cable structure and parameter

| Item | Contents | Unit | Value |

| Optical Fiber | model number | / | G657A1/G657A2/OM2/OM3/OM4 |

| number | / | 2 | |

| Color | / | nature | |

| Tight buffer | color | / | White |

| material | / | LSZH | |

| diameter | mm | 0.85±0.05 | |

| Sub-unit cable | Strength member | / | Aramid yarn |

| Jacket color | / | yellow、yellow | |

| Jacket material | / | LSZH | |

| Number | / | 2 | |

| Diameter | mm | 1.9±0.1 | |

| Fill the rope | Strength member | / | Aramid yarn |

| color | / | Black | |

| material | / | LSZH | |

| Number | / | 2 | |

| Diameter | mm | 2.0±0.1 | |

| Outer jacket | Diameter | mm | 7.0±0.2 |

| Material | / | LSZH | |

| Color | / | Black | |

| Cable attenuation | dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm | |

| Cable weight (Approx.) | kg/km | 41.8 | |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Tensile load | Short term | 200N fiber strain≤0.33% |

| Long term | 100N | |

| Crush resistance | Short term | 2200 |

| Long term | 1100 | |

| Min. bending radius | Installation | 25 x cable diameter |

| Operation | 12.5 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Optical fiber technical parameters-SM

| Parameter | Conditions | Units | Value | |||

| G652D | G657A1 | G657A2 | G657B3 | |||

| Optical Specification | ||||||

| Attenuation | 1310 nm | dB/km | ≤0.350 | ≤0.350 | ≤0.350 | ≤0.350 |

| 1383 nm | dB/km | ≤0.330 | ≤0.350 | ≤0.350 | ≤0.350 | |

| 1550 nm | dB/km | ≤0.210 | ≤0.210 | ≤0.210 | ≤0.210 | |

| 1625 nm | dB/km | ≤0.240 | ≤0.230 | ≤0.230 | ≤0.230 | |

| Attenuation vs. Wavelength | 1310 nm VS. 1285-1330 nm | dB/km | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.03 |

| 1550 nm VS. 1525-1575 nm | dB/km | ≤0.03 | ≤0.03 | ≤0.04 | ≤0.02 | |

| 1550 nm VS. 1480-1580 nm | dB/km | ≤0.04 | – | – | – | |

| Zero Dispersion Wavelength | \ | nm | 1300-1324 | 1300-1324 | 1300-1324 | 1300-1324 |

| Zero Dispersion Slope | ps/(nm2·km) | 0.073-0.092 | 0.073-0.092 | 0.073-0.092 | ≤0.092 | |

| Dispersion | 1550 nm | ps/(nm·km) | 13.3-18.6 | 13.3-18.6 | 13.3-18.6 | |

| 1625 nm | ps/(nm·km) | 17.2-23.7 | 17.2-23.7 | 17.2-23.7 | ||

| Polarization Mode Dispersion (PMD) | ps/√km | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

| Cut-off Wavelength λcc | – | nm | ≤1260 | ≤1260 | ≤1260 | ≤1260 |

| Mode Field Diameter (MFD) | 1310 nm | μm | 9.2±0.4 | 9.2±0.4 | 8.6±0.4 | 8.6±0.4 |

| 1550 nm | μm | 10.4±0.5 | 10.4±0.5 | 9.6±0.5 | 9.6±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 |

| 1550 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Bidirectional Attenuation | 1310 nm | dB/km | ≤0.04 | ≤0.05 | ||

| 1550 nm | dB/km | ≤0.04 | ≤0.05 | |||

| Geometrical | ||||||

| Cladding Diameter | μm | 125±0.7 | 125±0.7 | 125±0.7 | 125±0.7 | |

| Cladding Non-Circularity | % | ≤1.0 | ≤1.0 | ≤0.8 | ≤0.7 | |

| Core/Cladding Concentricity Error | μm | ≤0.6 | ≤0.5 | ≤0.5 | ≤0.5 | |

| Coating Diameter (Uncolored) | μm | 242±7 (standard) | ||||

| μm | 200±10 (optional) | |||||

| Coating/Cladding Concentricity Error | μm | ≤12 | ≤12 | ≤12 | ≤12 | |

| Curl | m | ≥4 | ≥4 | ≥4 | ≥4 | |

| Environmental (1550nm, 1625nm) | ||||||

| Temperature Cycling | -60℃ to +85℃ | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature &

High Humidity |

85℃, 85% RH, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Water Immersion | 23℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature Aging | 85℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

Optical fiber technical parameters-MM

| Features | Conditions | unit | Value | ||||

| OM1 | OM2 | OM2+ | OM3 | OM4 | |||

| Optical Characteristics | |||||||

| Attenuation | 850nm | dB/km | ≤2.70~≤3.00 | ≤2.50 | ≤2.50 | ≤2.50 | ≤2.50 |

| 1300nm | dB/km | ≤0.60~≤1.00 | ≤0.70 | ≤0.70 | ≤0.70 | ≤0.70 | |

| Minimum Modal Bandwidth | 850nm | MHz.km | ≥200~≥100 | ≥500~≥200 | – | – | – |

| 1300nm | MHz.km | ≥600~≥160 | ≥1200~≥400 | – | – | – | |

| Overfilled Launch Bandwidth | 850nm | MHz.km | – | – | ≥700 | ≥1500 | ≥3500 |

| 1300nm | MHz.km | – | – | ≥500 | ≥500 | ≥500 | |

| Effective Modal Bandwidth | 850nm | MHz.km | – | – | ≥950 | ≥2000 | ≥4700 |

| Numerical Aperture | 0.275±0.015 | 0.18~0.215 | |||||

| 10Gb/s Ethernet link length | M | – | – | 150 | 300 | 550 | |

| Backscatter Characteristics(1300nm) | |||||||

| Irregularities over fiber length and point discontinuity | dB | ≤0.1 | |||||

| Attenuation uniformity | dB | ≤0.1 | |||||

| Step (Mean of bidirectional(measurement) | dB/km | ≤0.1 | |||||

| Geometry Characteristics | |||||||

| Core Diameter | μm | 62.5±2.5 | 50±2.5 | ||||

| Core non-circularity | % | ≤5.0 | |||||

| Cladding Diameter | μm | 124.3±0.7 | |||||

| Cladding non-circularity | % | ≤2.0 | |||||

| Core/Cladding Concentricity Error | μm | ≤1.5 | |||||

| Coating Diameter | μm | 245±10 | |||||

| Coating/Cladding Concentricity Error | μm | ≤12.0 | |||||

| Delivery Length | km/reel | ~16.8 | |||||

| Environmental characteristics(850nm &1300nm) | |||||||

| Temperature dependence induced attenuation | -60℃~+85℃ | dB/km | ≤0.10 | ||||

| Temperature-humidity cycling deduced attenuation | -10℃~+85℃,98%RH | dB/km | ≤0.10 | ||||

| Water soak dependence induced attenuation | 23℃±2℃,30 days | dB/km | ≤0.10 | ||||

| Damp heat dependence induced attenuation | 85℃±2℃and85%RH,30 days | dB/km | ≤0.10 | ||||

| Dry heat aging | 85℃±2℃ | dB/km | ≤0.10 | ||||

Test Methods

| Test | Conditions | Acceptance criteria |

| Tensile strength IEC 60794-1-2 E1 | Tensile load: see Point 3 Sample length: ≥ 50 m Test duration: 1 min | – Fiber strain ≤0.6%

– No damage to outer jacket and inner elements |

| Crush resistance IEC 60794-1-2 E3 | Crush: see Point 3 Test duration: 5 min

Number of tests: 3 |

– Additional attenuation: ≤0.1dB after test

– No damage to outer jacket and inner elements |

| Impact

IEC 60794-1-2 E4 |

Impact Energy: 1J R=300 mm

Impact points: 3 Impact number: 1 |

– No obvious additional attenuation

– No damage |

| Repeated bending IEC 60794-1-2-E11A | Bending radius: 15x cable dia. Turn number: 4

Cycles: 3 |

– No obvious additional attenuation

– No damage |

| Torsion

IEC 60794-1-2 E7 |

Sample length: 2 m: Angles: ± 180°

Cycles: 10 |

– No obvious additional attenuation

– No damage |

| Temperature cycling IEC 60794-1-2 F1 | Steps: -30°C~+60°C

12 hours Cycles: 2 |

– Δα ≤ 0.15 dB/km

– Attenuation reversible – No damage |

| Water penetration IEC 60794-1-2 F5 | Sample length: 3 m

Water column height: 1 m Duration: 24 h |

– No water leak through the open end in 24 h |

| Filling compound flow

IEC 60794-1-2-E14 |

Sample length: 0.2 m 60°C

Duration: 24 h |

– No compound flow from the cable in 24 h |