Description

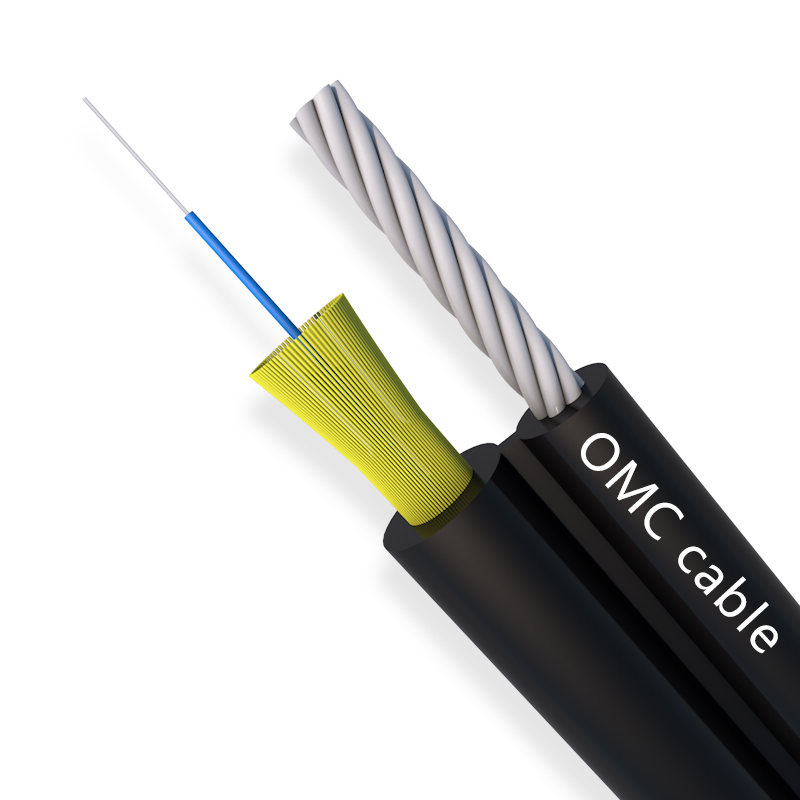

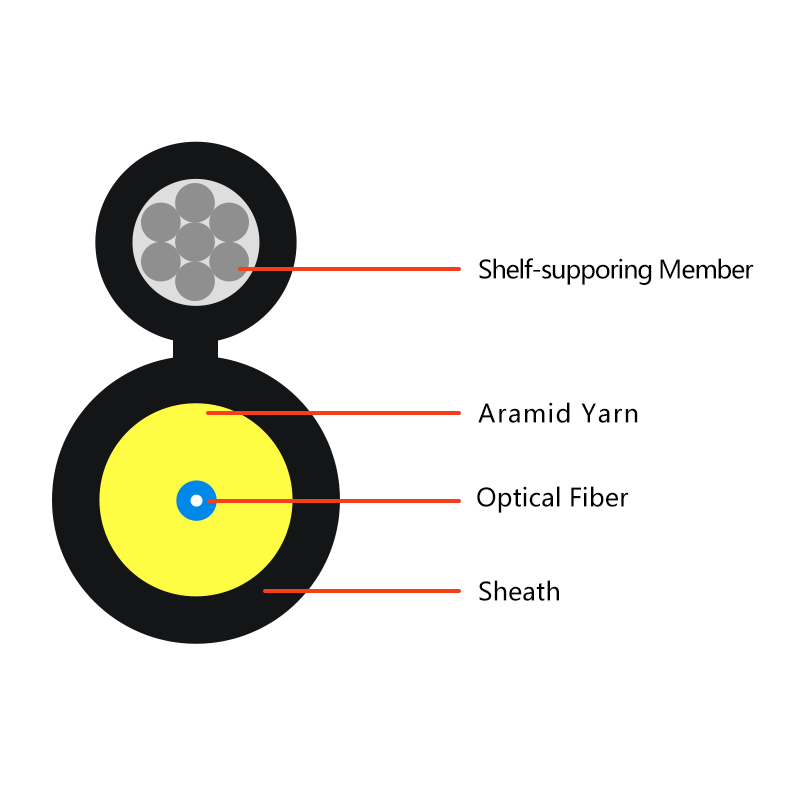

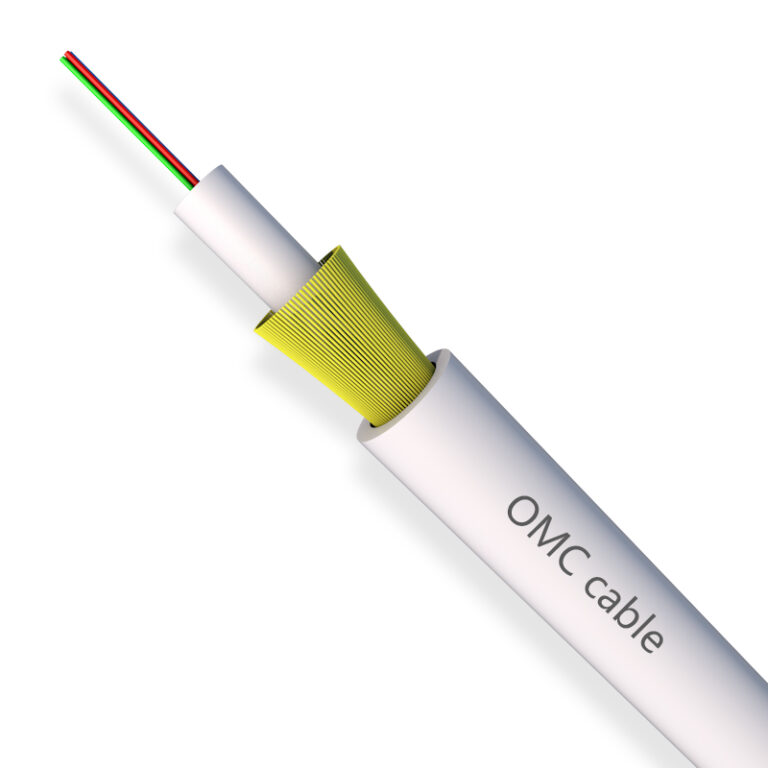

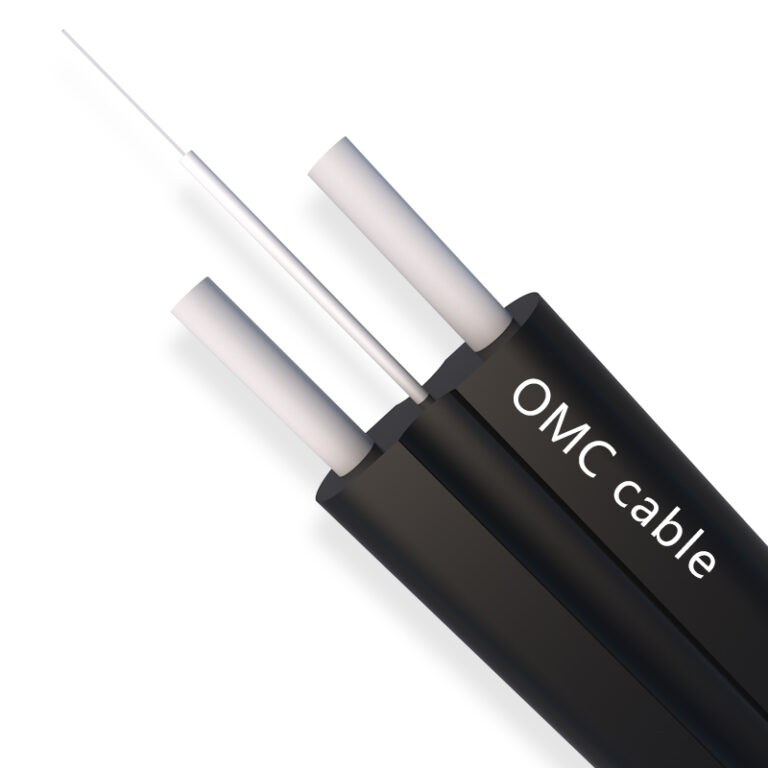

1F Fig 8 Self – supporting FTTH Drop Cable is a kind of self-supporting FTTH Drop cable for aerial installation. This cable is in a figure 8 shape. The cable part is a round – type 2.0mm OD cable. The self – supporting member is a strand of steel wire which is made from 7 pieces of 0.33mm steel wire. These form a strong self – supporting member. So this is a very good choice for an aerial FTTH cabling solution.

Cable Parameters

| Items | Specifications | |

| Fiber Count | 1 | |

| Semi-Tight Buffer Fiber | Dimension | 0.87±0.05mm |

| Material | PVC&LSZH | |

| Color | Blue | |

| Jacket | Dimension | (2.0±0.1)mm×(2.5±0.1)mm—(4.9±0.2)mm |

| Material | LSZH with UV Protection | |

| Color | Black | |

| Strength Member | Aramid yarn | |

| Self-supporting member | Galvanized Steel Wire 7*0.33mm | |

| Weight of Cable | 13Kg/Km approx | |

Mechanical Characteristics

| Items | Unite | Specifications |

| Tension(Long Term) | N | 300 |

| Tension(Short Term) | N | 600 |

| Crush(Long Term) | N/10cm | 100 |

| Crush(Short Term) | N/10cm | 500 |

| Min. Bend Radius(Dynamic) | mm | 20D |

| Min. Bend Radius(Static) | mm | 10D |

ENVIRONMENTAL PARAMETERS

| Item | Standard | Specification |

| Environmental | IEC-60794-1-22-F5B | No water penetration |

| IEC-60794-1-22-F9 | ≤0.1dB/km max. attenuation change allowed | |

| Application temperature range | Application temperature range ℃ | Operation: – 10℃ ~ +70℃

Installation: -40℃ ~ +70℃ Storage/transportation: – 40℃ ~ +70℃ |

Application

Outdoor aerial application

Used in the FTTH projects

High speed optical routes in building

High performance optical network operation

Cable Marking

Brand Manufacture Date(YR/MT) Model Number of cores Category carrier Number of Reel Meter(xxxxM)

*OEM MARKING IS AVAIABLE, The marking can be changed according to customer requirements.

Optical fiber type and properties

| Parameter | Conditions | Units | Value | |||

| G652D | G657A1 | G657A2 | G657B3 | |||

| Optical Specification | ||||||

| Attenuation | 850 nm | dB/km | – | – | – | – |

| 1300 nm | dB/km | – | – | – | – | |

| 1310 nm | dB/km | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | |

| 1383 nm | dB/km | ≤ 0.330 | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | |

| 1550 nm | dB/km | ≤ 0.210 | ≤ 0.210 | ≤ 0.210 | ≤ 0.210 | |

| 1625 nm | dB/km | ≤ 0.240 | ≤ 0.230 | ≤ 0.230 | ≤ 0.230 | |

| Attenuation vs. Wavelength | 1310 nm VS. 1285-1330 nm | dB/km | ≤ 0.04 | ≤ 0.04 | ≤ 0.05 | ≤ 0.03 |

| 1550 nm VS. 1525-1575 nm | dB/km | ≤ 0.03 | ≤ 0.03 | ≤ 0.04 | ≤ 0.02 | |

| 1550 nm VS. 1480-1580 nm | dB/km | ≤ 0.04 | – | – | – | |

| Zero Dispersion Wavelength | \ | nm | 1300-1324 | 1300-1324 | 1300-1324 | 1300-1324 |

| Zero Dispersion Slope | ps/(nm2·km) | 0.073-0.092 | 0.073-0.092 | 0.073-0.092 | ≤ 0.092 | |

| Dispersion | 1550 nm | ps/(nm·km) | 13.3-18.6 | 13.3-18.6 | 13.3-18.6 | |

| 1625 nm | ps/(nm·km) | 17.2-23.7 | 17.2-23.7 | 17.2-23.7 | ||

| Polarization Mode Dispersion (PMD) | ps/√km | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

| Cut-off Wavelength λcc | – | nm | ≤1260 | ≤1260 | ≤1260 | ≤1260 |

| Mode Field Diameter (MFD) | 1310 nm | μm | 9.2±0.4 | 9.2±0.4 | 8.6±0.4 | 8.6±0.4 |

| 1550 nm | μm | 10.4±0.5 | 10.4±0.5 | 9.6±0.5 | 9.6±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 |

| 1550 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Bidirectional Attenuation | 1310 nm | dB/km | ≤0.04 | ≤0.05 | ||

| 1550 nm | dB/km | ≤0.04 | ≤0.05 | |||

| Geometrical | ||||||

| Cladding Diameter | μm | 125±0.7 | 125±0.7 | 125±0.7 | 125±0.7 | |

| Cladding Non-Circularity | % | ≤1.0 | ≤1.0 | ≤0.8 | ≤0.7 | |

| Core/Cladding Concentricity Error | μm | ≤0.6 | ≤0.5 | ≤0.5 | ≤0.5 | |

| Coating Diameter (Uncolored) | μm | 242±7 (standard) | ||||

| μm | 200±10 (optional) | |||||

| Coating/Cladding Concentricity Error | μm | ≤12 | ≤12 | ≤12 | ≤12 | |

| Curl | m | ≥4 | ≥4 | ≥4 | ≥4 | |

| Environmental (1550nm, 1625nm) | ||||||

| Temperature Cycling | -60℃ to +85℃ | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature &

High Humidity |

85℃, 85% RH, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Water Immersion | 23℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature Aging | 85℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |