Description

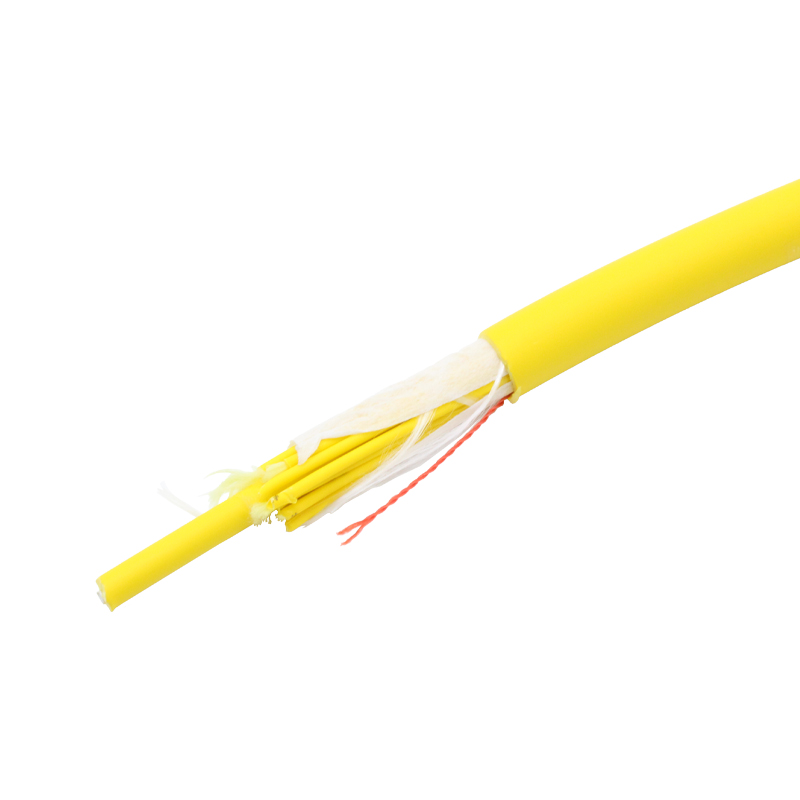

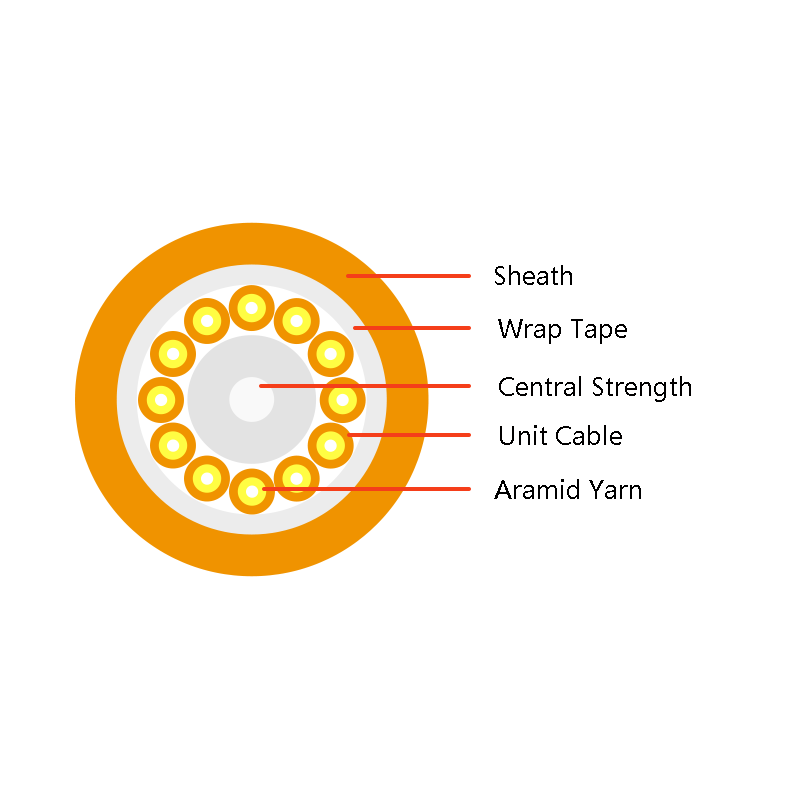

Fiber breakout cable, also be called bunch fanout fiber cable. In OMC’s 12F Unit-tube Distribution cable-fanout 2.0mm cable, A fiber reinforced plastic (FRP) wire, sometimes sheathed with polyethylene (PE) is located in the center of cable as a No-metallic strength member. 12pcs of 2.0mm OD Single-mode/multimode Sub cable as optical communication medium, the sub cables were wrapped with a layer of wrap yarn. Finally, a LSZH or PVC or OFNR or OFNP jacket sheath covered the warp yarn to finish the cable.

Features:

Stranded non-metallic strength member structure ensure the cable endure large tensile strength

Select quality fiber to ensure excellent transmission performance

Adopt strict process and raw materials control to guarantee the lifespan of 15 years

The jacket anti-corrosion, anti-water, anti-ultraviolet radiation, flame-retardant and harmless to environment.

Cable Color

| Fiber Mode | SM | SM | SM | SM | OM2 | OM3 |

| Color | Yellow | Blue | White | Ivory | Orange | Aqua |

| Fiber Mode | OM4 | OM4 | OM4 | OM4 | OM5 | OM1 |

| Color | Magenta | Purple | Aqua | Violet | Lemon Green | Orange |

Cable Material parameter

| Item | Parameters | |

| Fiber Type | G652D,G655,G657A1,G657A2,G657B3,OM1,OM2,OM3,OM4,OM5 | |

| Fiber Count | 12 | |

| Tight buffer | Material | LSZH or PVC |

| OD | 0.9±0.05(mm) | |

| Strength Member | Material | Aramid Yarn |

| Central strength member | Material | FRP &PE cushion layer(when need) |

| Outer Sheath | OD | 12.5±0.5(mm) |

| Material | LSZH,PVC,OFNR,OFNP | |

Mechanical & Environmental Performance

| Items | Descriptions | ||

| Tensile Strength | IEC 60794-1-E1 | short-term | 1200N |

| long-term | 400N | ||

| Crush Resistance | IEC 60794-1-E3 | short-term | 1500N |

| long-term | 500N | ||

| Cable Impact | IEC 60794-1-E4 | No obvious change after test | |

| Repeat Bending | IEC 60794-1-E6 | ||

| Torsion | IEC 60794-1-E7 | ||

| Cable Bend | IEC 60794-1-E11 | ||

| Temperature Range(operation) | IEC 60794-1-2-F1 | -20℃-+60℃ | |

| Temperature Range(storage) | IEC 60794-1-2-F1 | -20℃-+60℃ | |

| Bending Radius | Static | 10XCable Diameter | |

| Dynamic | 20XCable Diameter | ||

Flame retardant Performance

| Cable material | Standard |

| LSZH | CPR : Bca, Cca, Dca, Eca Or IEC60332-1, IEC 60332-3 According to customer demand |

| PVC | UL-94V0 |

Optical fiber technical parameters-SM

| Parameter | Conditions | Units | Value | |||

| G652D | G657A1 | G657A2 | G657B3 | |||

| Optical Specification | ||||||

| Attenuation | 850 nm | dB/km | – | – | – | – |

| 1300 nm | dB/km | – | – | – | – | |

| 1310 nm | dB/km | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | |

| 1383 nm | dB/km | ≤ 0.330 | ≤ 0.350 | ≤ 0.350 | ≤ 0.350 | |

| 1550 nm | dB/km | ≤ 0.210 | ≤ 0.210 | ≤ 0.210 | ≤ 0.210 | |

| 1625 nm | dB/km | ≤ 0.240 | ≤ 0.230 | ≤ 0.230 | ≤ 0.230 | |

| Attenuation vs. Wavelength | 1310 nm VS. 1285-1330 nm | dB/km | ≤ 0.04 | ≤ 0.04 | ≤ 0.05 | ≤ 0.03 |

| 1550 nm VS. 1525-1575 nm | dB/km | ≤ 0.03 | ≤ 0.03 | ≤ 0.04 | ≤ 0.02 | |

| 1550 nm VS. 1480-1580 nm | dB/km | ≤ 0.04 | – | – | – | |

| Zero Dispersion Wavelength | – | nm | 1300-1324 | 1300-1324 | 1300-1324 | 1300-1324 |

| Zero Dispersion Slope | ps/(nm2·km) | 0.073-0.092 | 0.073-0.092 | 0.073-0.092 | ≤ 0.092 | |

| Dispersion | 1550 nm | ps/(nm·km) | 13.3-18.6 | 13.3-18.6 | 13.3-18.6 | |

| 1625 nm | ps/(nm·km) | 17.2-23.7 | 17.2-23.7 | 17.2-23.7 | ||

| Polarization Mode Dispersion (PMD) | ps/√km | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

| Cut-off Wavelength λcc | – | nm | ≤1260 | ≤1260 | ≤1260 | ≤1260 |

| Mode Field Diameter (MFD) | 1310 nm | μm | 9.2±0.4 | 9.2±0.4 | 8.6±0.4 | 8.6±0.4 |

| 1550 nm | μm | 10.4±0.5 | 10.4±0.5 | 9.6±0.5 | 9.6±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 |

| 1550 nm | dB | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Bidirectional Attenuation | 1310 nm | dB/km | ≤0.04 | ≤0.05 | ||

| 1550 nm | dB/km | ≤0.04 | ≤0.05 | |||

| Geometrical | ||||||

| Cladding Diameter | μm | 125±0.7 | 125±0.7 | 125±0.7 | 125±0.7 | |

| Cladding Non-Circularity | % | ≤1.0 | ≤1.0 | ≤0.8 | ≤0.7 | |

| Core/Cladding Concentricity Error | μm | ≤0.6 | ≤0.5 | ≤0.5 | ≤0.5 | |

| Coating Diameter (Uncolored) | μm | 242±7 (standard) | ||||

| μm | 200±10 (optional) | |||||

| Coating/Cladding Concentricity Error | μm | ≤12 | ≤12 | ≤12 | ≤12 | |

| Curl | m | ≥4 | ≥4 | ≥4 | ≥4 | |

| Environmental (1550nm, 1625nm) | ||||||

| Temperature Cycling | -60℃ to +85℃ | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature &

High Humidity |

85℃, 85% RH, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Water Immersion | 23℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| High Temperature Aging | 85℃, 30days | dB/km | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

Optical fiber technical parameters-MM

| Features | Conditions | unit | Value | ||||

| OM1 | OM2 | OM2+ | OM3 | OM4 | |||

| Optical Characteristics | |||||||

| Attenuation | 850nm | dB/km | ≤2.70~≤3.00 | ≤2.50 | ≤2.50 | ≤2.50 | ≤2.50 |

| 1300nm | dB/km | ≤0.60~≤1.00 | ≤0.70 | ≤0.70 | ≤0.70 | ≤0.70 | |

| Minimum Modal Bandwidth | 850nm | MHz.km | ≥200~≥100 | ≥500~≥200 | – | – | – |

| 1300nm | MHz.km | ≥600~≥160 | ≥1200~≥400 | – | – | – | |

| Overfilled Launch Bandwidth | 850nm | MHz.km | – | – | ≥700 | ≥1500 | ≥3500 |

| 1300nm | MHz.km | – | – | ≥500 | ≥500 | ≥500 | |

| Effective Modal Bandwidth | 850nm | MHz.km | – | – | ≥950 | ≥2000 | ≥4700 |

| Numerical Aperture | 0.275±0.015 | 0.18~0.215 | |||||

| 10Gb/s Ethernet link length | M | – | – | 150 | 300 | 550 | |

| Backscatter Characteristics(1300nm) | |||||||

| Irregularities over fiber length and point discontinuity | dB | ≤0.1 | |||||

| Attenuation uniformity | dB | ≤0.1 | |||||

| Step (Mean of bidirectional(measurement) | dB/km | ≤0.1 | |||||

| Geometry Characteristics | |||||||

| Core Diameter | μm | 62.5±2.5 | 50±2.5 | ||||

| Core non-circularity | % | ≤5.0 | |||||

| Cladding Diameter | μm | 124.3±0.7 | |||||

| Cladding non-circularity | % | ≤2.0 | |||||

| Core/Cladding Concentricity Error | μm | ≤1.5 | |||||

| Coating Diameter | μm | 245±10 | |||||

| Coating/Cladding Concentricity Error | μm | ≤12.0 | |||||

| Delivery Length | km/reel | ~16.8 | |||||

| Environmental characteristics(850nm &1300nm) | |||||||

| Temperature dependence induced attenuation | -60℃~+85℃ | dB/km | ≤0.10 | ||||

| Temperature-humidity cycling deduced attenuation | -10℃~+85℃,98%RH | dB/km | ≤0.10 | ||||

| Water soak dependence induced attenuation | 23℃±2℃,30 days | dB/km | ≤0.10 | ||||

| Damp heat dependence induced attenuation | 85℃±2℃and85%RH,30 days | dB/km | ≤0.10 | ||||

| Dry heat aging | 85℃±2℃ | dB/km | ≤0.10 | ||||

Application

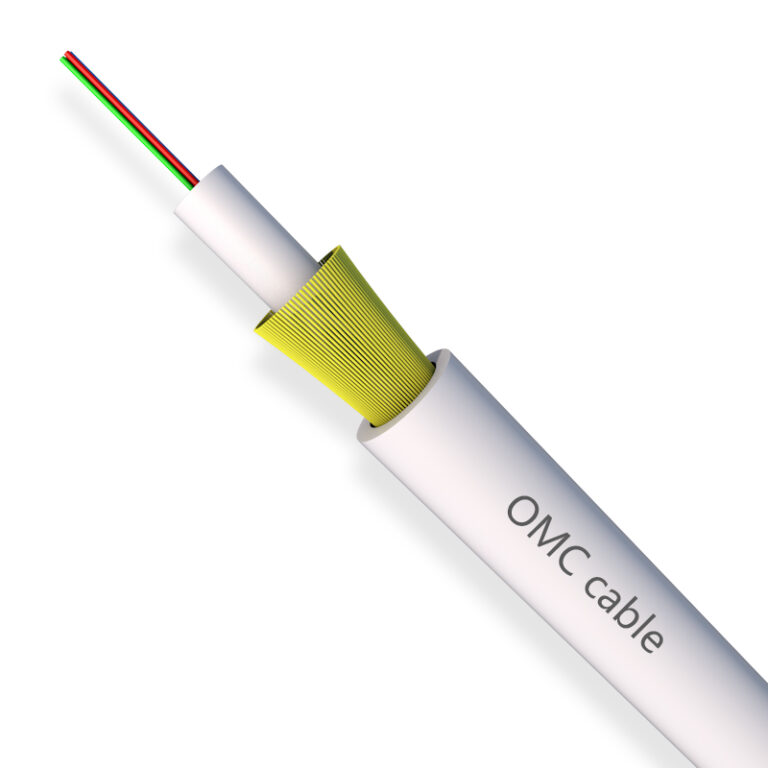

Used in pigtails and patch cords

Used as interconnect lines of equipment and used in optical connections in optical communication rooms and optical distribution frames