Description

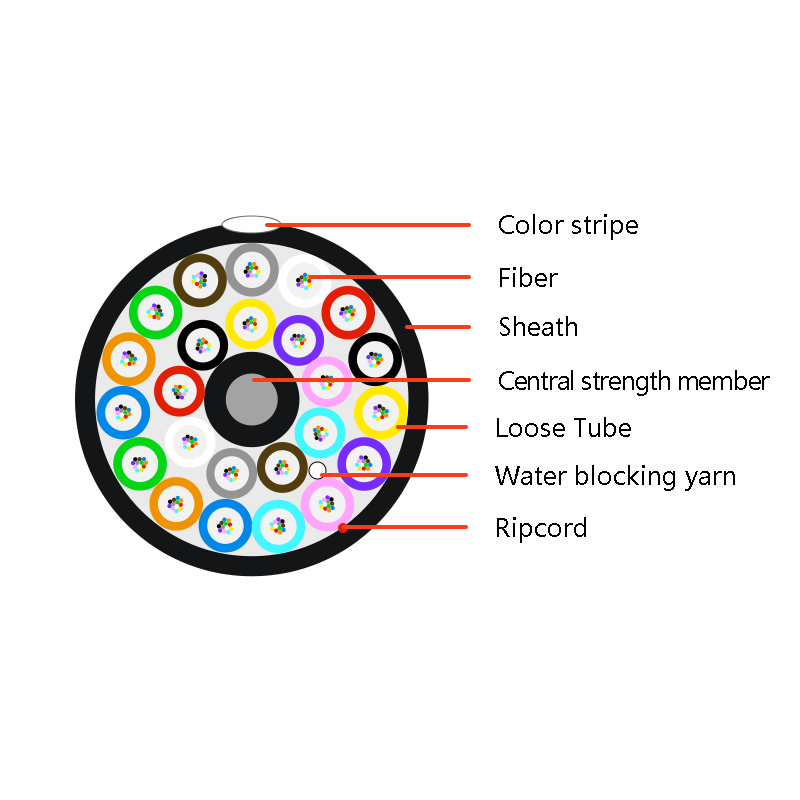

In OMC’s 12-288F Stranded Loose Tube No-Armored outdoor cable-GCYTY, A FRP wire, sometimes sheathed with polyethylene (PE) is located in the center of core as a No-metallic strength member. single-mode/multimode Fiber are positioned in the loose tube, which is made of PBT materials and filled with filling compound. The loose tube is covered with PE materials to guarantee the compactness and longitudinal water-blocking performance.

Standard color of fiber and tube

The color code of the individual fibers, shall be in accordance with the table as below

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Tube color code for 12~144 fibers:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Inner layer loose tubes color code for 288 fibers:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | |||

| Color | Red | Black | Yellow | |||

| No. | 10 | 11 | 12 | 13 | 14 | 15 |

| Color | Violet | Pink | Aqua | Blue # | Orange # | Green # |

| No. | 16 | 17 | 18 | 19 | 20 | 21 |

| Color | Brown # | Gray # | White # | Red # | Black * | Yellow # |

| No. | 22 | 23 | 24 | |||

| Color | Violet # | Pink # | Aqua # | |||

Outer layer loose tubes color code for 288 fibers

Note: # means single black stripe; * means single white stripe.

Structure parameter

| Item | Contents | Unit | Value | |||||

| Fiber count | Number | / | 12 | 24 | 48 | 96 | 144 | 288 |

| Cable structure | / | / | 1+6 | 1+6 | 1+6 | 1+8 | 1+12 | 1+9+15 |

| Fiber No. per tube | Number | / | 12 | 12 | 12 | 12 | 12 | 12 |

| Loose tube | Number | / | 1 | 2 | 4 | 8 | 12 | 9+15 |

| Central strength member | Material | / | FRP with cushion when necessary | |||||

| Cable diameter | ±5% | mm | 5.3 | 5.3 | 5.3 | 6.2 | 8.0 | 9.4 |

| Cable weight | ±10% | kg/km | 22 | 22 | 23 | 35 | 53 | 77 |

| Micro duct inner diameter | / | mm | 8 | 8 | 8 | 8 | 10 | 14 |

Mechanical & Environmental Performance

| Item | Test Method | Acceptance Condition |

| Tensile Strength IEC 60794-1-21-E1 | – Load: Short term tension

– Length of cable: ≥ 50m – Load time: 1min |

Loss change≤0.1dB@1550nm after test.

No fiber break and no sheath damage. |

| Crush Test

IEC 60794-1-21-E3 |

– Load: Short term crush

– Load time: 1min |

Loss change≤0.1dB@1550nm after test.

No fiber break and no sheath damage. |

| Impact Test

IEC 60794-1-21-E4 |

– Points of impact: 3

– Times of per point: 1 – Impact energy: 1J |

Loss change≤0.1dB@1550nm after test.

No fiber break and no sheath damage. |

| Repeated Bending

IEC 60794-1-21-E6 |

– Bending radius: 20 x OD

– No. of cycles: 25 |

Loss change≤ 0.1dB@1550nm after test.

No fiber break and no sheath damage. |

| Torsion

IEC 60794-1-21-E7 |

– Length: 2m

– Twist angle: ±180° – No. of cycles: 10 |

Loss change≤0.1dB@1550nm after test.

No fiber break and no sheath damage. |

| Water Penetration IEC 60794-1-22-F5 | – Height of water: 1m

– Sample length: 3m – Time: 24h |

No water leak from the cable core of the opposite end |

| Temperature Cycling IEC 60794-1-22-F1 | – Temperature: -20℃~+70℃

– Time of each step: 12h – No. of cycles: 2 |

Loss change≤0.1dB/km@1550nm after test.

– No fiber break and no sheath damage. |

Optical fiber technical parameters-SMF

| Item | Contents | Value |

|

Attenuation |

@1310nm | ≤0.36dB/km |

| @1550nm | ≤0.22dB/km | |

|

Dispersion |

@1288nm~1339nm | ≤3.5ps/(nm·km) |

| @1550nm | ≤18ps/(nm·km) | |

| @1625nm | ≤22ps/(nm·km) | |

| Zero-Dispersion wavelength | 1300nm~1324nm | |

| Zero-Dispersion slope | ≤0.092ps/(nm2·km) | |

| Mode field diameter

(MFD) |

@1310nm | 9.2±0.4μm |

| @1550nm | 10.4±0.8μm | |

| Cable cutoff wavelength λcc(nm) | ≤1260nm | |

|

Bending loss |

1550nm (1 turn; Φ20mm) | £0.75dB |

| 1550nm (10 turns; Φ30mm) | £0.25dB | |

| 1625nm (1 turn; Φ20mm) | £1.5dB | |

| 1625nm (10 turns; Φ30mm) | £1.0dB | |

| Geometrical characteristics | ||

| Cladding diameter | 125±1.0μm | |

| Cladding non-circularity | ≤1% | |

| Core/cladding concentricity error | ≤0.6μm | |

| Cladding/coating concentricity error | ≤12.0μm | |

| Mechanical characteristics | ||

| Proof stress | ≥0.69GPa | |

| Fiber curl | ≥4m | |

| Coating strip force | 1.0~8.9N | |