Description

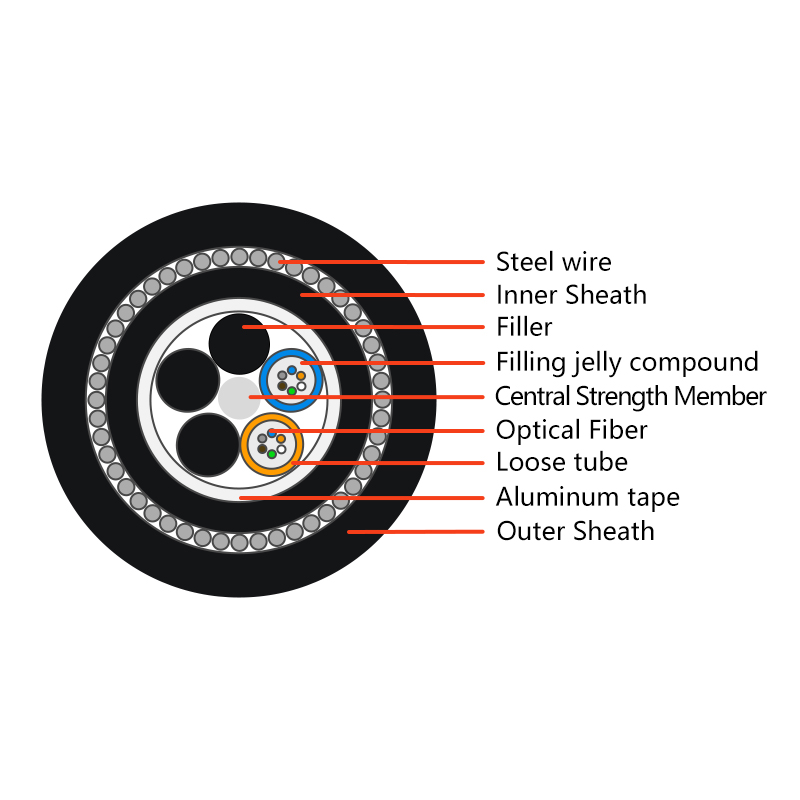

In OMC’s 4-144F Stranded Loose Tube Double Armored&Sheath (GYTA33) PE cable, A Phosphating steel wire is located in the center of core as a metallic strength member. single-mode/multimode Fiber are positioned in the loose tube, which is made of PBT materials and filled with filling compound. The tubes (and fillers) are stranded around the strength member into a compact and circular core. An aluminum Polyethylene Laminate (APL) is applied around the cable core. Then the APL is covered with a thin polyethylene (PE) inner sheath, which is filled with jelly to protect it from water ingress. Then a Galvanized steel wire armor is applied, the cable is completed with a PE outer sheath.

Standard color of fiber and tube

The color code of the individual fibers, shall be in accordance with the table as below

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Tube color code for 12~144 fibers:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Note: # means single black stripe; * means single white stripe.

Cable Structure parameter

| Fiber count | Structure | Fibers per tube | Loose tube diameter(mm) | CSM diameter/pad diameter(mm) | Nominal Thickness of Inner jacket(mm) | Nominal Thickness of outer jacket(mm) | Cable diameter (mm) | Cable weight

(kg/km) |

| 4 | 1+5 | 4 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 269 |

| 6 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 269 |

| 8 | 1+5 | 4 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 270 |

| 12 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 270 |

| 18 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 270 |

| 24 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 271 |

| 30 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.0±0.5 | 271 |

| 36 | 1+6 | 6 | 1.7±0.1 | 1.8/1.8 | 0.9 | 1.8 | 13.5±0.5 | 292 |

| 48 | 1+5 | 12 | 2.0±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.7±0.5 | 295 |

| 60 | 1+5 | 12 | 2.0±0.1 | 1.4/1.4 | 0.9 | 1.8 | 13.7±0.5 | 296 |

| 72 | 1+6 | 12 | 2.0±0.1 | 2.0/2.0 | 0.9 | 1.8 | 14.4±0.5 | 335 |

| 84 | 1+7 | 12 | 2.0±0.1 | 1.8/2.9 | 0.9 | 1.8 | 15.3±0.5 | 365 |

| 96 | 1+8 | 12 | 2.0±0.1 | 1.8/3.5 | 0.9 | 1.8 | 16.0±0.5 | 389 |

| 108 | 1+9 | 12 | 2.0±0.1 | 1.8/4.2 | 0.9 | 1.8 | 16.7±0.5 | 421 |

| 120 | 1+10 | 12 | 2.0±0.1 | 1.8/4.9 | 0.9 | 1.8 | 17.4±0.5 | 448 |

| 132 | 1+11 | 12 | 2.0±0.1 | 1.8/5.5 | 0.9 | 1.8 | 18.6±0.5 | 563 |

| 144 | 1+12 | 12 | 2.0±0.1 | 1.8/6.3 | 0.9 | 1.8 | 19.4±0.5 | 601 |

Cable Material parameter

| Item | Parameters | |

| Loose tube | Material | PBT |

| Color | Full color spectrum | |

| Filler | Material | PE |

| Color | Black | |

| CSM | Material | Phosphating steel wire |

| Armoured | Material | Plastic coated aluminum strip |

| Steel wire Armoured | Material | Galvanized steel wire |

| Inner jacket | Material | PE |

| Color | Black | |

| Outer jacket | Material | PE |

| Color | Black | |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 10000N fiber strain≤0.6% |

| Long term | 5000N | |

| Max. crush resistance | Short term | 5000N/100mm |

| Long term | 3000N/100mm | |

| Min. bending radius | Installation | 25 x cable diameter |

| Operation | 12.5 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Standards: IEC 60794-1

Optical fiber technical parameters

| Fiber style | Unit | SM 9/125 | MM 50/125 | MM 62.5/125 | |

| Condition | nm | 1310/1550 | 850/1300 | 850/1300 | |

| Attenuation | dB/km | ≤0.34/0.2 | ≤3.0/1.0 | ≤3.0/1.0 | |

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ….. | ….. |

| 1550nm | Ps/(nm*km) | ≤22 | ….. | ….. | |

| Bandwidth | 850nm | MHZ. KM | ….. | ≧400 | ≧160 |

| 1300nm | MHZ. KM | ….. | ≧800 | ≧500 | |

| Zero dispersion wavelength | nm | ≧1302,

≤1322 |

….. | ….. | |

| Zero dispersion slope | nm | ≤0.091 | ….. | ….. | |

| PMD Maximum Individual Fiber | ≤0.2 | ….. | ….. | ||

| PMD Design Link Value | Ps(nm2*km) | ≤0.08 | ….. | ….. | |

| Fiber cutoff wavelength λc | nm | ≧1180,

≤1330 |

….. | ….. | |

| Cable cutoff wavelength λcc | nm | ≤1260 | ….. | ….. | |

| MFD | 1310nm | um | 9.2±0.4 | ….. | ….. |

| 1550nm | um | 10.4±0.8 | ….. | ….. | |

| Numerical Aperture(NA) | …… | 0.200±0.015 | 0.275±0.015 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.08 | ≤0.10 | |

| Attenuation uniformity | dB/km | ≤0.01 | ……. | ……. | |

| Core diameter | um | …… | 50±1.0 | 62.5±2.5 | |

| Cladding diameter | um | 125.0±0.1 | 125.0±0.1 | 125.0±0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242±7 | 242±7 | 242±7 | |

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | |

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding concentricity error | um | ≤0.6 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ….. | ….. | |