Description

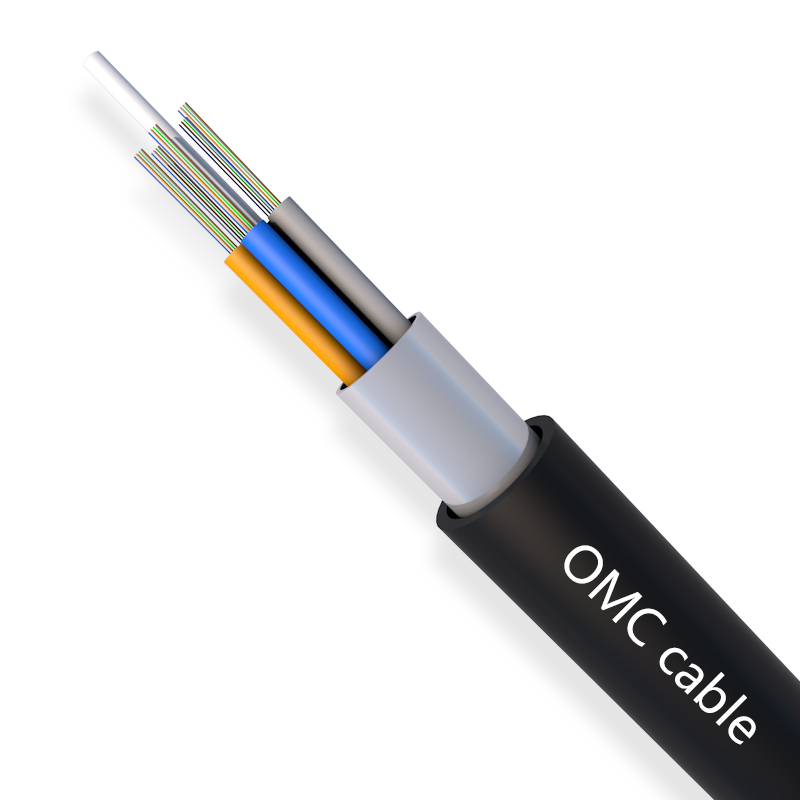

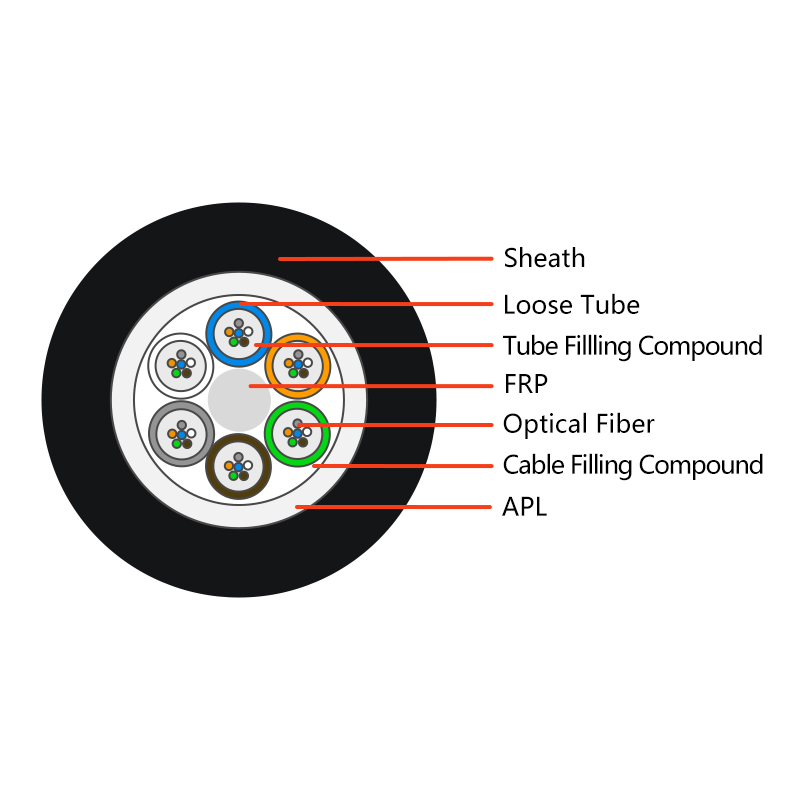

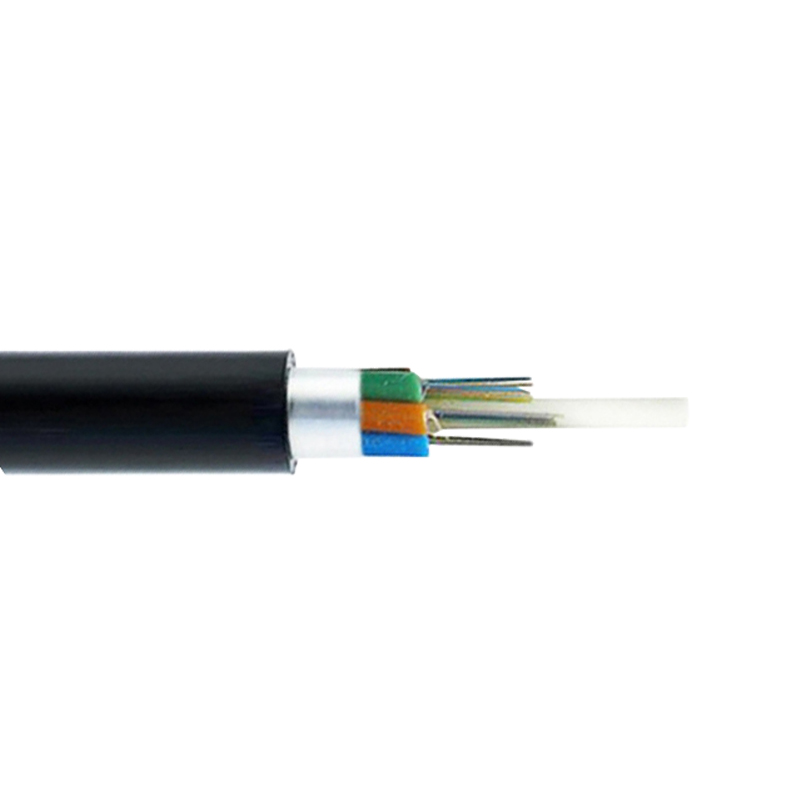

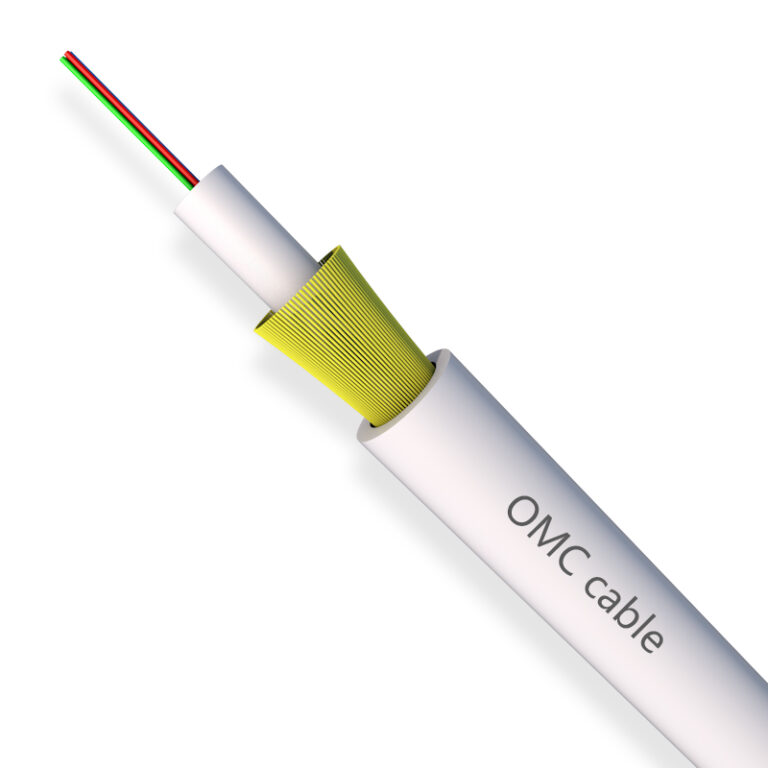

In OMC’s 2-96F Stranded Loose Tube Armored (GYFTA) type Cable, A FRP wire, sometimes sheathed with polyethylene (PE) is located in the center of core as a No-metallic strength member. Single-mode/multimode Fiber are positioned in the loose tube, which is made of PBT materials and filled with filling compound. PBT Tubes (and fillers) are stranded around the Central strength member into a compact and circular cable core. After a APL armor is applied, The PE materials Jacket covered to guarantee the compactness and longitudinal water-blocking performance.

Standard color of fiber and tube

The color code of the individual fibers, shall be in accordance with the table as below

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Tube color code for 12~144 fibers:

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Gray | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Note: # means single black stripe; * means single white stripe.

Cable Structure parameter

| Item | Contents | Unit | Value | ||||

| Fiber count | Number | / | 2~8 | 12~24 | 48 | 72 | 96 |

| Fiber type | / | / | G652D | ||||

| Cable structure | / | / | 1+6 | 1+6 | 1+6 | 1+8 | |

| Fibers per tube | Count | / | 2-6 | 12 | 12 | 12 | |

| Loose tube | Material | / | PBT | ||||

| Nominal Diameter | mm | 1.9 | 2.2 | 2.2 | 2.2 | ||

| Central strength member | Material | / | FRP &PE cushion layer(when need) | ||||

| Nominal Diameter | mm | 2.2 | 2.4 | 2.4 | 2.4 | ||

| PE cushion layer | mm | – | – | 3.8±0.2 | |||

| Peripheral strength member | Material | Aluminum tape | |||||

| Outer sheath | Material | PE | |||||

| Color | Black | ||||||

| thickness | mm | Nominal:2.0 | |||||

| Attenuation (after cable) | 1310nm | dB/km | £0.36 | ||||

| 1550nm | dB/km | £0.22 | |||||

| Cable diameter | ±5% | mm | 10.3 | 10.3 | 11.1 | 11.1 | 13.0 |

| Cable weight | ±10% | kg/km | 84 | 85 | 98 | 98 | 136 |

Mechanical & Environmental Performance

| Item | Contents | Value |

| Max. tensile load | Short term | 3000N fiber strain≤0.6% |

| Long term | 1500N | |

| Max. crush resistance | Short term | 3000N/100mm |

| Long term | 1000N/100mm | |

| Min. bending radius | Installation | 20 x cable diameter |

| Operation | 10 x cable diameter | |

| Temperature range | Operation | -40℃ ~ +70℃ |

| Installation | -20℃ ~ +60℃ | |

| Storage/transportation | -40℃ ~ +70℃ |

Optical fiber technical parameters

| Fiber style | Unit | SM 9/125 | MM 50/125 | MM 62.5/125 | |

| Condition | nm | 1310/1550 | 850/1300 | 850/1300 | |

| Attenuation | dB/km | ≤0.34/0.2 | ≤3.0/1.0 | ≤3.0/1.0 | |

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ….. | ….. |

| 1550nm | Ps/(nm*km) | ≤22 | ….. | ….. | |

| Bandwidth | 850nm | MHZ. KM | ….. | ≧400 | ≧160 |

| 1300nm | MHZ. KM | ….. | ≧800 | ≧500 | |

| Zero dispersion wavelength | nm | ≧1302,

≤1322 |

….. | ….. | |

| Zero dispersion slope | nm | ≤0.091 | ….. | ….. | |

| PMD Maximum Individual Fiber | ≤0.2 | ….. | ….. | ||

| PMD Design Link Value | Ps(nm2*km) | ≤0.08 | ….. | ….. | |

| Fiber cutoff wavelength λc | nm | ≧1180,

≤1330 |

….. | ….. | |

| Cable cutoff wavelength λcc | nm | ≤1260 | ….. | ….. | |

| MFD | 1310nm | um | 9.2±0.4 | ….. | ….. |

| 1550nm | um | 10.4±0.8 | ….. | ….. | |

| Numerical Aperture(NA) | …… | 0.200±0.015 | 0.275±0.015 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.10 | ≤0.10 | |

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.08 | ≤0.10 | |

| Attenuation uniformity | dB/km | ≤0.01 | ……. | ……. | |

| Core diameter | um | …… | 50±1.0 | 62.5±2.5 | |

| Cladding diameter | um | 125.0±0.1 | 125.0±0.1 | 125.0±0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242±7 | 242±7 | 242±7 | |

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | |

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding concentricity error | um | ≤0.6 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ….. | ….. | |